- Region: United States

US-AB boosts capacity with Plockmatic’s automated creasing and folding machine and booklet maker

About Universitetsservice AB

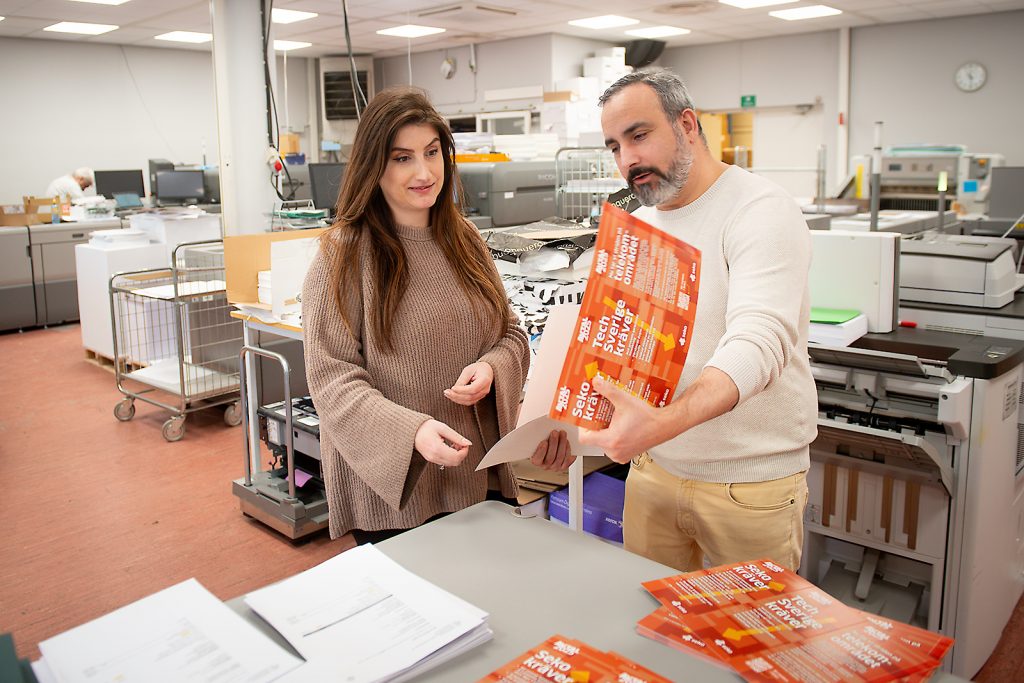

US-AB (Universitetsservice AB) is a print provider with over 20 years of experience, located on the campus of the Royal Institute of Technology (KTH) in Stockholm. The company specialises in printed materials for the academic sector, such as dissertations, course packs and student union publications. It is a contracted supplier to several universities and colleges in the Stockholm area.

To expand its business and reach new markets, US-AB has also broadened its customer base beyond academia. Today, the company works with real estate agencies, the tourism sector and private schools, all of which need high-quality printed materials with fast turnaround. This diversification has contributed to an increase in turnover of more than 70 percent over the past three years.

The machine line-up includes four Ricoh production printers, including two newly added Ricoh Pro C9500 presses, selected for their ability to handle heavier substrates and increase automation in production.

US-AB invests in flexibility and production efficiency

US-AB already had a Plockmatic booklet maker integrated inline with one of its Ricoh printers – a solution chosen to fully automate the production process from print to finished booklet. Inline solutions are highly effective for fully automated production.

However, in its most recent investment, the company opted for a offline booklet making system. This was partly due to space limitations, but also to improve overall efficiency. By separating the finishing stage, there’s no need to wait for each print job to be completed before booklet production can begin. Instead, printed output from multiple devices can be collected and processed in one continuous flow.

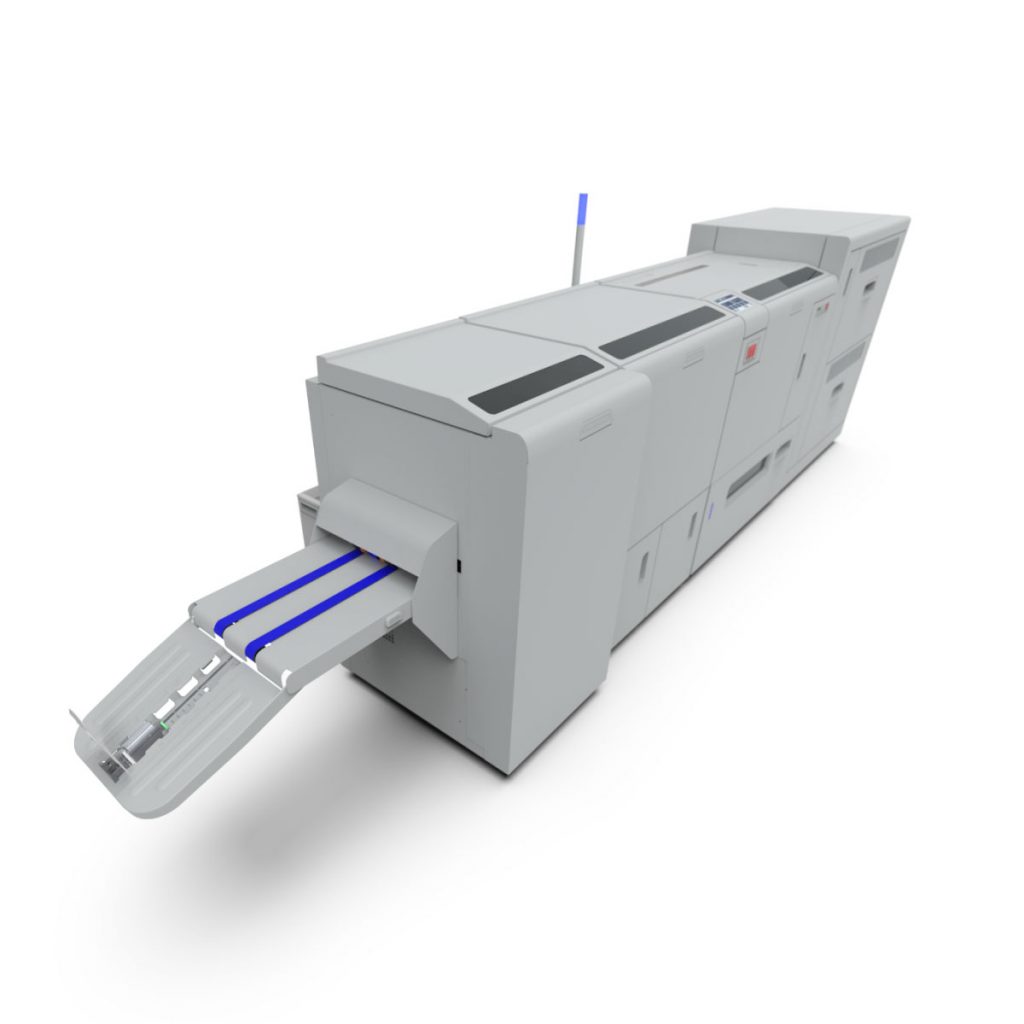

The solution was the Plockmatic BM5000. The system handles everything from feeding and creasing to folding, stitching and three-side trimming in a fully automated workflow. With support for formats up to landscape A4 and SquareFold spine as standard, it’s a versatile solution built for both high volume and format flexibility.

“We’re now 20 percent more efficient in our booklet production,” he says, also highlighting the flexibility of the wide format range from A4 down to A6″

Josef Lotfi, CEO, US-AB

The system handles everything from feeding, creasing and folding to stitching and trimming in an automated workflow. It eliminates the need for separate creasing machines, saving time and streamlining the production process.

“We can now produce significantly more – thanks to the volume capacity, and because we avoid manual steps like trimming top and bottom edges. It’s a big upgrade for our entire finishing operation.” Josef Lotfi, CEO, US-AB

Automated creasing and folding with DigiFold Pro XL

US-AB has also recently invested in a Morgana DigiFold Pro XL, an automated creasing and folding machine from Plockmatic. After issues with a previous solution from another manufacturer, the company chose DigiFold Pro XL – a machine capable of handling long and heavy media types with high precision and consistent speed.

With support for a wide range of crease and fold combinations, US-AB can now offer its customers a broader selection of brochures, folded pieces and other print applications. This opens the door to new applications, such as covers for landscape booklets, book covers for oversized perfect bound books, multi-panel brochures, and many other folded products made from long sheets.

This automated creasing and folding machine can crease, fold and perforate up to 6,000 A4 sheets per hour. It handles paper weights from 80 to 400 gsm and media lengths up to 1,300 mm, making it ideal for both standard and specialty formats.

International

International United Kingdom - Morgana

United Kingdom - Morgana Baltic

Baltic Norway

Norway Sweden

Sweden USA

USA