Richardson & Son, based in Hawick in the Scottish Borders, has invested in a Morgana AutoCreaser Pro XL, purchased through Morgana dealer CLC.

- Region: United States

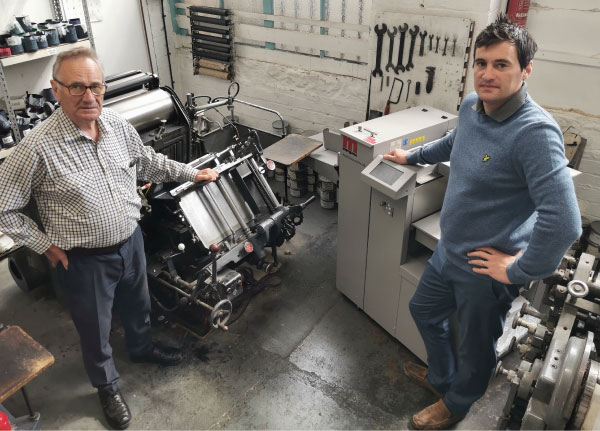

AutoCreaser Pro XL for Richardson & Son, Hawick

Commenting on the need for the AutoCreaser Pro XL, Jamie Richardson, Co-Director, said:

“We do a lot of creasing and perforating on our Thomson Platen machines, but it takes quite a bit of skill and time to make-ready those machines. A lot of the jobs we do are small runs, like sock bands and swing tags, for example, so make-ready was taking longer than the time to actually produce the work.”

“One of the team had seen something about more automated creasing products online, so we made enquiries to three of our print finishing equipment suppliers. All of them came back with the same answer – that the Morgana AutoCreaser Pro XL would be able to handle our needs. We knew the Morgana team, as we have a few other Morgana machines on-site, so then, because of our location, we needed to find the best service solution as well as the best price. Although pricing was pretty close between them all, CLC offered an on-site demo, so in the end we went with them.”

Would this new arrival make the existing trusty platen products redundant? “No, we’ve kept the platens, and our Titan cylinder. Although the Titan will probably never run again, we are not really short of space, and it is an impressive bit of kit – also I guess we could be a little sentimental. The platens though are still used for die-cutting, and creasing heavier stock on a regular basis.”

The Morgana AutoCreaser Pro XL paper creasing system is an easy-to-use product with a highly efficient vacuum top feeder. The unique creasing rule in the AutoCreaser Pro XL eliminates paper tearing and, therefore, cracking. The Pro XL runs at a maximum of 8,500 A4 sheets per hour, with no loss of accuracy.

The product is Morgana’s most productive creaser to date, complete with the ability to handle longer sheets. The new AutoCreaser Pro XL takes a sheet size of up to 385 x 1,300mm with the table extension. Its feeder boasts an ultrasonic double sheet detection, an inline rotary perforation system with the capacity for up to five perforations at the same time, as well as the option of a cross perforation unit.

“The machine has done a lot of varied tasks. It perforates our raffle tickets, creases menus, order of service sheets, greeting cards, sock bands, swing tickets, and many more. The biggest plus, of course, is the make-ready time between jobs – it’s just so quick and simple. The machine runs every day, doing a variety of different jobs, and has definitely helped us increase our productivity.”

About Richardson & Sons

Richardson & Sons is a family run business based in Hawick, Scottish Borders. Established in 1946 by Jimmy “The Printer” Richardson, the company started out from premises at Dovemount Place and remained there until 2001 when it moved to the old Hawick News building, Lochpark Industrial Estate. From here it continues to offer a range of professional printing and finishing services to the public and the trade. The running of the business continued with Murray Richardson taking over when his father retired, and is now run by Murray, his wife Ebie, and their son Jamie. The business has grown from strength-to-strength with three other employees: David Finnie, our printer, who has worked with us for over 40 years; Robert Scott, our graphic designer and pre-press operator; and Christine Rodger, our secretary and book keeper.

For more information, see richardsonprinters.com

International

International United Kingdom - Morgana

United Kingdom - Morgana Baltic

Baltic Norway

Norway Sweden

Sweden USA

USA