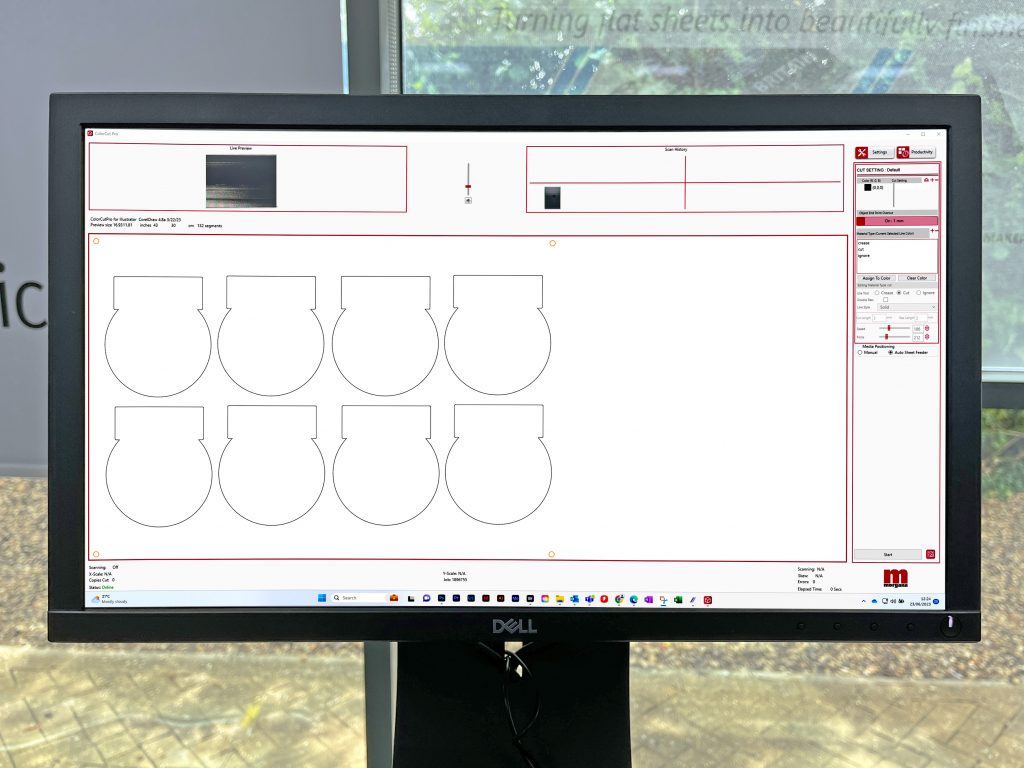

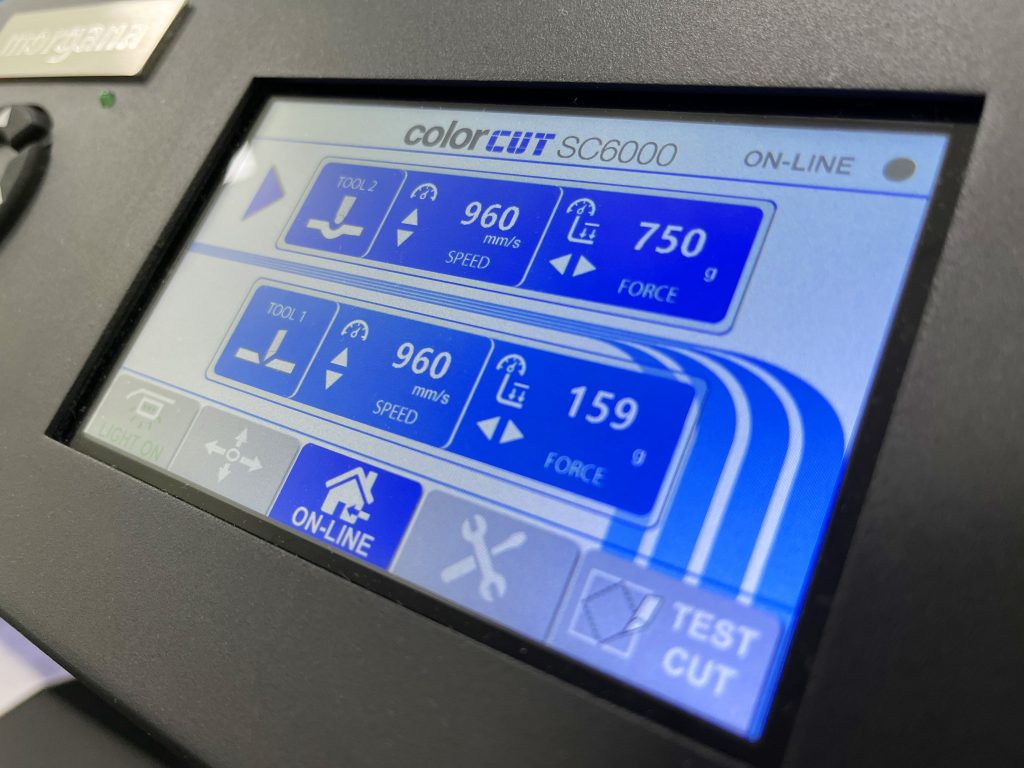

John Brailsford Printers, “Yorkshire’s Favourite, Fast, Friendly Quick Printer!”, has become the first UK print business to install a Morgana ColorCut SC6000 digital die-cutting and creasing machine. Morgana Systems Ltd, Milton Keynes, a Plockmatic International post-press product business, debuted the product earlier this year at the Hunkeler Innovation Days.

ColorCut SC6000 is a freestanding, “on-demand” digital sheet cutter and creaser, with no physical cutting dies or time-consuming set-up costs. The unit is targeted at busy print businesses seeking an affordable, high-capacity device, capable of completely unattended cutting production. The compact, free-standing device is conveniently mobile, and can be easily accommodated in any print shop. It is ideal for the production of labels, stickers, display materials, short run packaging work, and other “any shape” cut-out jobs.

John Brailsford Printers, the Rotherham shop-fronted business, had reviewed a number of potential products in the cutting and creasing sector, but nothing quite fitted the bill.

International

International United Kingdom - Morgana

United Kingdom - Morgana Baltic

Baltic Norway

Norway Sweden

Sweden USA

USA