- Region: United States

The CT XL unit trims the top and bottom edges off the sheets, and it can also crease each sheet as it passes through the module. This enables a number of new applications to be produced with Ricoh printing systems. This means that full bleed, creased booklets can be produced with the Ricoh Booklet Maker finisher SR5120.

The side trim slitting design is based on the well proven RCT module for the Plockmatic PBM350 system, now with a new registration process to enable registration of long sheets (up to 1260mm).

The Crease function enhances book appearance by reducing or eliminating “cracking” of toner on the spine. It also provides a better fold on thicker stock.

The CT XL will enable full bleed book production with the Ricoh SR5120 Booklet Finisher. The CT XL will trim top and bottom of the sheets as they pass through the module on their way to the Ricoh finisher.

The side trim slitting design is based on the well proven RCT module for the Plockmatic PBM350 system with a new registration process to enable registration of long sheets (up to 1260mm).

The CT XL can trim the side edges of sheet sizes up to 1260mm or 49.6” long. This can overcome some of the challenges faced by small print shops who may only have a guillotine able to process sheets up to 520cm / 20’’

The CT XL enables new super long sheet applications to be created, an example of which is extra long Ceiling Banners.

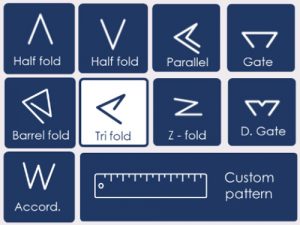

The CT XL can also put up to 3 crease lines in to the sheets. This enables new Long Sheet fold applications. Nine standard crease patterns plus custom crease pattern are available

Creased Sheets will be delivered to the SR5110/SR5210 shift tray or to the Plockmatic long sheet stacker MPS XL where the operator can easily fold the application along the crease lines or finish the job in an offline fold unit that lacks the crease feature.