Zone Graphics, based in Paddock Wood, Kent, is a digital and litho print business with a keen eye on delivering high quality work, including those jobs that some printers might shy away from.

- Region: United States

Zone Graphics – Purchases Valiani Optima

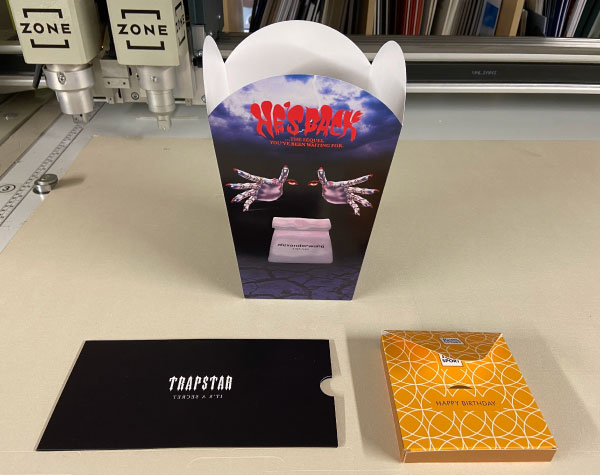

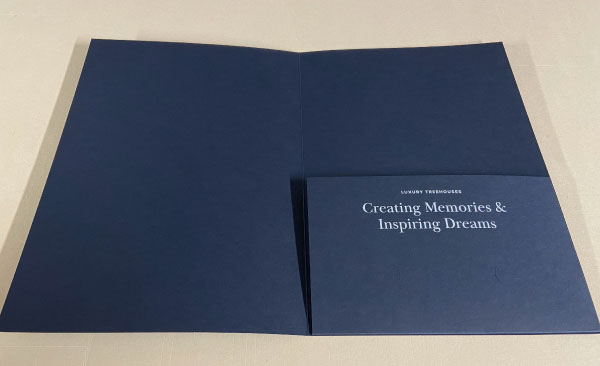

An equipment purchase made just prior to the crazy Covid pandemic years has helped to keep the business going forward by winning new and profitable work. The Valiani Optima flat-bed cutting device, purchased through UK distributor Morgana Systems, was initially acquired to make the production of pocket-folders more efficient, along with handling a growing demand for short-run carton and box work.

The introduction to the machine took place at an SOS print event at Brands Hatch. Morgana were also exhibiting there, and they introduced us to the Valiani.

“An industry friend – Nick Murray of Wellington Press – was there. He was already a user, and was very enthusiastic about the machine, suggesting that it could be a great addition for us. We spoke in some detail with Morgana, and we managed to get a good deal from them for the machine that was at the show, as an ex-demo model.”

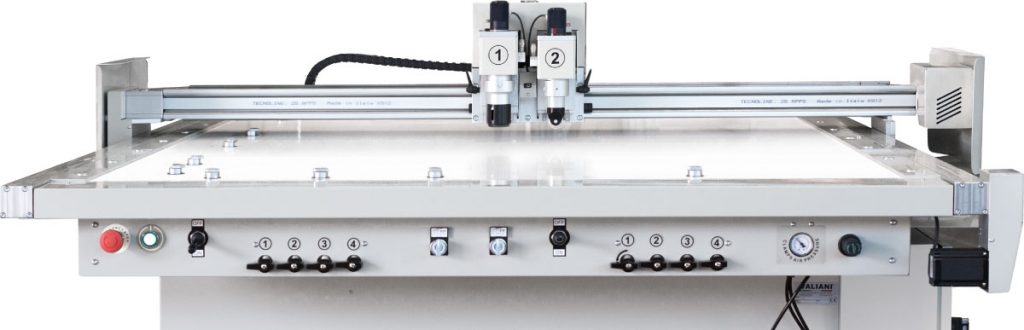

The Valiani Optima series of digital cutting tables provide the user with an extended range of finishing processes, beginning with the critical tasks of cutting and creasing on large format sheets. Further tools allow a user to meet the requirements of many markets and applications in the offset and digital print arena, as well as to produce work for the POS display and the packaging sectors. It’s the ideal solution for short to medium runs of die-cutting, short-run box production, carton prototyping, and much more. Precision, reliability and flexibility are the key features of all Valiani products. Simple and intuitive to use, the Optima series incorporate a refined cutting technology that can satisfy the most demanding of users.

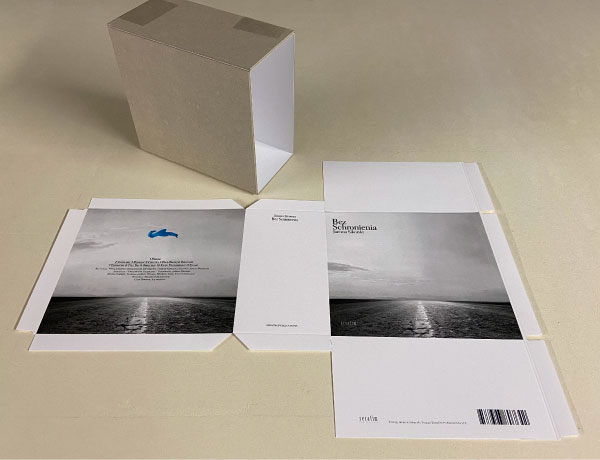

“Whilst we were initially focused on the production of pocket-folders, the Valiani has enabled us to tackle a much wider range of work – much of it we could not even have imagined. In addition, our production of cartons and boxes has grown beyond belief. The cutting and creasing capabilities of the machine allow us to produce a much wider selection, in a wide range of sizes. In the past, each size and format would have required a different cutting forme to go onto the Platen, each with a cost attached. The Valiani is simply guided by the sized details that we enter into the system. It’s relatively straightforward to operate as well. Once the set-up is done, anybody in the factory can load and unload the stock.”

“A good deal of the work we were winning during the early months of the pandemic was what I would describe as “High End”. A print management company that we have worked with for several years enquired about one particularly intricate job for a well-known up-market London store: it consisted of several thousand prints of 200-hundred different sized labels, all with very exacting cut and score requirements – printed type just one or two millimetres from the trim in some instances, for example.”

“OK, we could gang-up impositions of up to 250 copies at once, reducing the actual print run to just few dozen copies, but the cutting and scoring was where the real work came in. That job took several weeks to complete, but it paid well – re-paying a nice chunk of the price of the Valiani – and we delivered a great job, on time.

“It’s now a job that is required on a regular basis. The print management company looked elsewhere to see if they could reduce the price by examining different production methods. They couldn’t find any. Certainly, the cost of producing the cutting formes would have made the job far too expensive to produce using a platen style of production. The work has now come back to us several times, in smaller quantities, but still a profitable job for us. And that’s just one example of an order that we couldn’t even have envisioned prior to getting an understanding of what the Valiani could do for us.”

In one other example, Jamie details the work undertaken for a company that produce racing car simulation machines. Delivered products are packaged with trays containing the components of the machine. Trays are made from 5mm and 3mm fluted cartonboard. The board requires a variety of creases which divide up the packaging into compartments. The manufacturer was inundated with orders for simulators as lockdown took hold, largely from drivers in competitive motor racing, so orders for the packaging element were an urgent requirement.

The Valiani Optima is initially supplied with cutting and scoring heads. Zone Graphics has purchased three additional tools for the Valiani as the company has expanded the range of work that it is undertaken: the kiss-cut head, the oscillating head, and the 45-degree cutting head.

Speaking two-and-a-half years on from the initial purchase, Jamie Marshall says:

“We couldn’t produce the wide range of work we now do without the Valiani, although our Platen is still also kept busy. The Valiani has allowed us to keep much more work in-house, whilst opening new doors for us – new customers and new work. It’s versatile, relatively simple to learn and operate, light weight – important for us as it’s positioned on a mezzanine floor – and requires just a 13-amp socket to operate. It’s helped us as a business to get through the pandemic by widening the types of work that we can produce and earn money from.”

“The Valiani is a well-constructed and reliable machine. First-line support from Morgana, coupled with some more detailed operator support direct from the Italian manufacturer, Valiani, have helped us to operate right through the various lockdowns, learning on the go with regards to what the unit can produce.”

International

International United Kingdom - Morgana

United Kingdom - Morgana Baltic

Baltic Norway

Norway Sweden

Sweden USA

USA