Snap Queen Street invests in Plockmatic Pro 35

- Region: United States +1 585 267 7692

Snap Queen Street invests in Plockmatic Pro 35

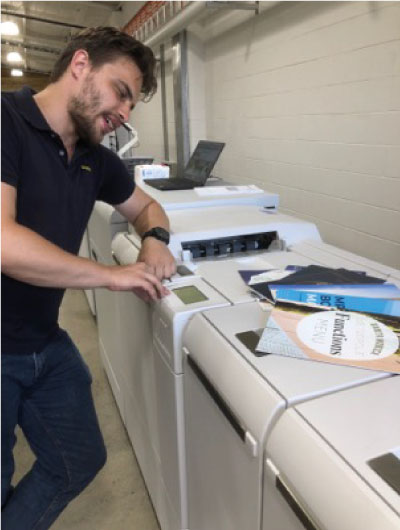

Snap Queen Street uses a remote site to produce much of the production work submitted into the city location. Simon Morcom is the franchisee and also owns the Snap in Maroochydore north of Brisbane and in Latrobe Melbourne. He has a Pro50 on Color 1000i at the Melbourne location, so familiar with the quality of Plockmatic products.

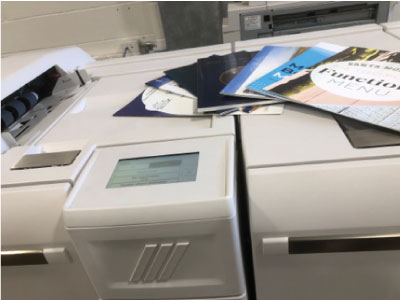

In addition to the Fuji Xerox Iridesse press, this location houses the Versant 180 and D110 printers. The main operators Dan and Jake, both expressed how easy the Pro35 is to set up and use. They enjoy that the books are completed at the same time as the printing. The team at this Snap need to operate many types of equipment, often simultaneously, to keep productivity high. The Pro35 fits well in this environment due to the automation and quality output.

Typical booklet jobs for this Snap are manuals and newsletters produced on 150-170gsm stock with covers up to 350gsm. The average book size is A4 with 40-60 pages. Asked what they would change or improve on the Pro35, the team agreed that the Cover Feeder could be more robust. Adding to the requirement for automation and less touchpoints, they cited the need for a cover feeder before the side trim module. For this reason, Simon will be adding a D1 inserter to the configuration.

The Pro35 is part of the Plockmatic family of 35 and 50 sheet booklet makers designed for Fuji Xerox printers. The robust design of the systems delivers the quality and precision that meets the requirements of either the CRD in-plant or commercial print environments. The adaptive folding technology, along with the trimming and creasing functions, guarantees the production of up to 140-page booklets in the most cost-effective way possible. The technology eliminates the risk of cracking of toner, thus enhancing the booklet’s appearance. Plockmatic’s Pro35/50 inline booklet makers are designed from the ground-up to work with today’s demanding paper stocks. The robust design of these systems makes it possible to produce booklets made from a wide range of media weights.

International

International United Kingdom - Morgana

United Kingdom - Morgana Baltic

Baltic Norway

Norway Sweden

Sweden USA

USA