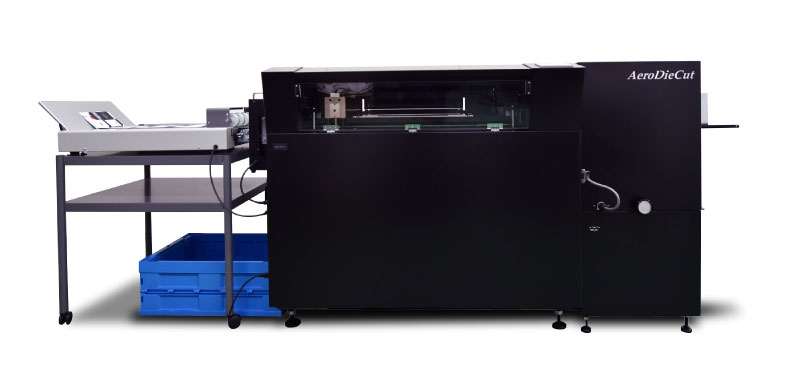

Lithuania based Artrema have chosen to invest in the new AeroDieCut for the production of small medical packaging. Having previously been using a Heidelberg cylinder made in the sixties for their cutting and creasing applications, the requirement to produce small run medical packaging has led to the AeroDieCut becoming the latest addition to their itinerary.

- Region: Sweden +46-8-6025000

Artrema invest in the new AeroDieCut

Cut, crease, and emboss / deboss all in one pass.

Although the Heidelberg cylinder is a highly capable machine, the AeroDieCut has a number of advantages over the 1960s technology, the main advantage being that it can cut, crease, and emboss / deboss all in one pass. This is ideal when producing medical packaging, where the use of braile is a legal requirement under European law. Adding to this, the device is easy to setup and removes the need of a skilled operator, and offers a much lower risk to health and safety. With all features it’s easy to see why the AeroDieCut is the obvious choice for future production.

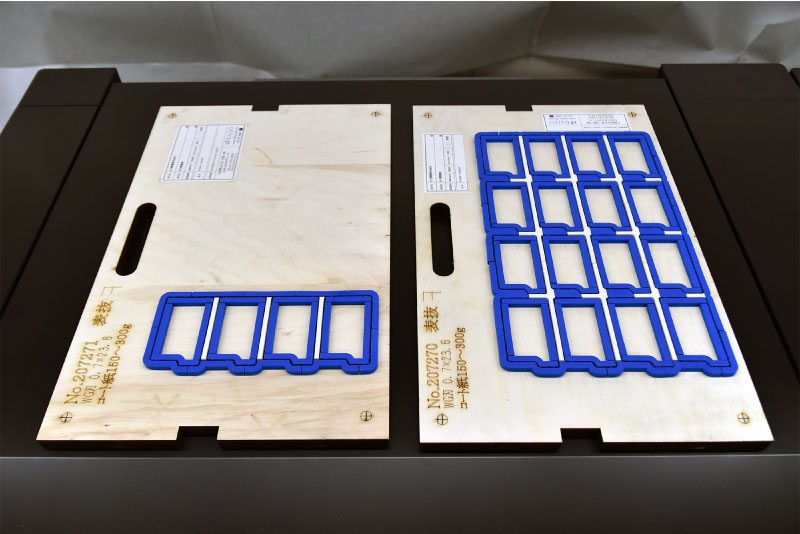

The AeroDieCut still utilizes traditional platen dies

Another advantage is that despite the improvements to die cutting technology, the AeroDieCut still utilizes traditional platen dies, which over the years have proven to be a reliable, easy to obtain and cost effective solution, producing a very high quality, professional finish.

International

International United Kingdom - Morgana

United Kingdom - Morgana Baltic

Baltic Norway

Norway Sweden

Sweden USA

USA