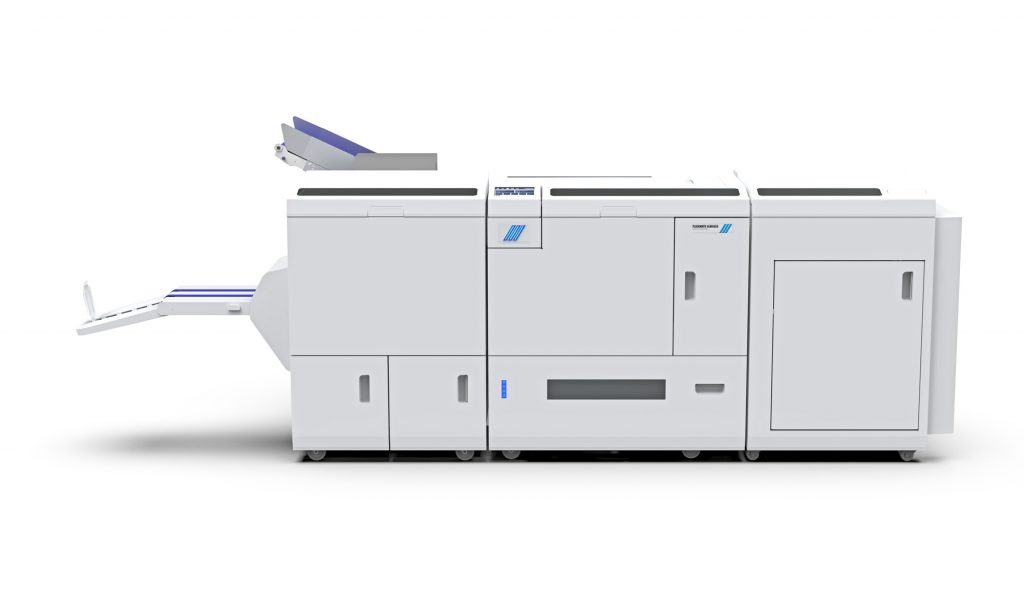

WhiteOak install Morgana BM4050 booklet maker

WhiteOak Printing, Lancaster, Pennsylvania (PA), USA, has become the latest printer to install a Morgana BM4050 booklet maker, manufactured by Morgana Systems Ltd, a Plockmatic International post-press product business.

The Morgana BM4000 suite of booklet makers, introduced in the third quarter of 2022, provide the finishing solution for work with low- to mid-volume digital production printers. The BM4050 delivers booklets of exceptional quality, and is able to feed long printed sheets to produce a wide variety of applications, including Letter-landscape format booklets, which are becoming increasingly popular with customers.

The new system at WhiteOak was installed and ready for action from the beginning of 2023. With regard to the arrival of the new booklet maker, Brad Kauffman, Production Manager at WhiteOak, said: “We have been familiar with Morgana equipment for some time – we have two Morgana AutoCreaser products – so when we were looking to change our existing booklet making machine, they were an obvious place for us to look.

International

International United Kingdom - Morgana

United Kingdom - Morgana Baltic

Baltic Norway

Norway Sweden

Sweden USA

USA