- Region: Norway +47 23898586

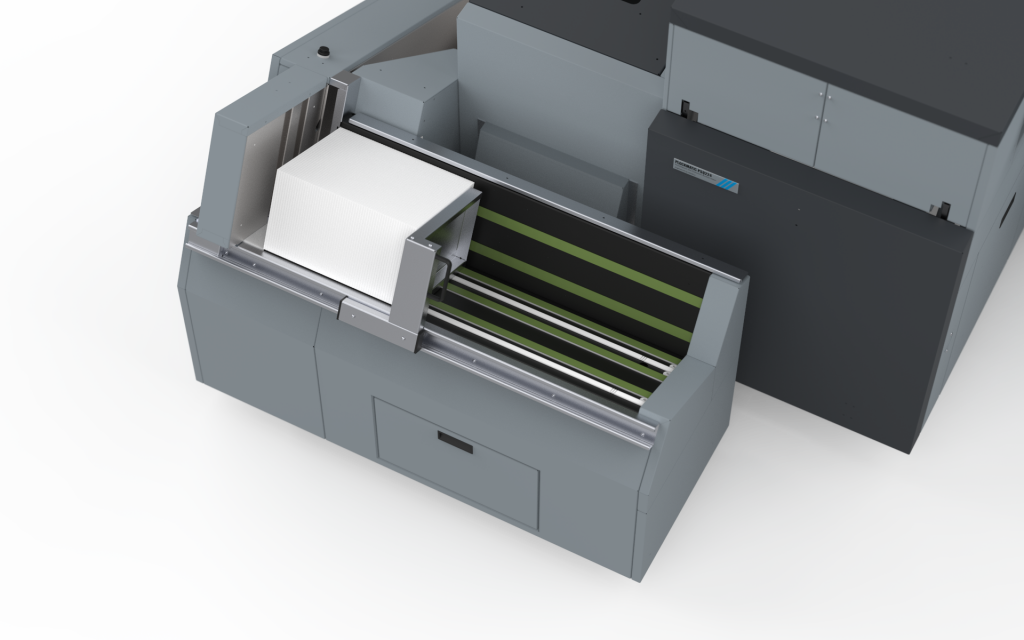

Full integration with the printer optimises performance and productivity. Printed sheets are delivered from the printer to the PowerSquare via a connecting bridge that automatically rotates the sheets into the correct orientation for booklet making to give a professional finish every time.

This system is designed for high reliability and ease of use, with the ability to handle long runs without any operator intervention. Its ergonomic layout means that the finished books are delivered close to the normal operator position, saving space, time and operator fatigue.

With the optional book stacker, the system will run for up to an hour unattended. The high capacity trim bin can be emptied without stopping the machine, and stitch wire refills are reduced by the use of a 15kg wire-reel that will produce approximately 130,000 books.

The inline PowerSquare is the most versatile inline booklet maker, from folding a single sheet to making 224 page booklets; and it can also be handfed for occasional use.

The PowerSquare Book Stacker (PBS) delivers huge efficiency gains by allowing the Watkiss PowerSquare to run, unattended, for extended periods.

The PBS stacks the finished books vertically which is extremely space efficient; and it requires very little additional floor space. With a capacity of 930mm, it can run for up to an hour without operator intervention. The stacker can be unloaded on-the-run and accommodates different sized books without adjustment to give uninterrupted production.

The PBS complements the PowerSquare’s capability for thick books and high volume production by streamlining the entire operation. The operator can set the machine running and simply walk away.

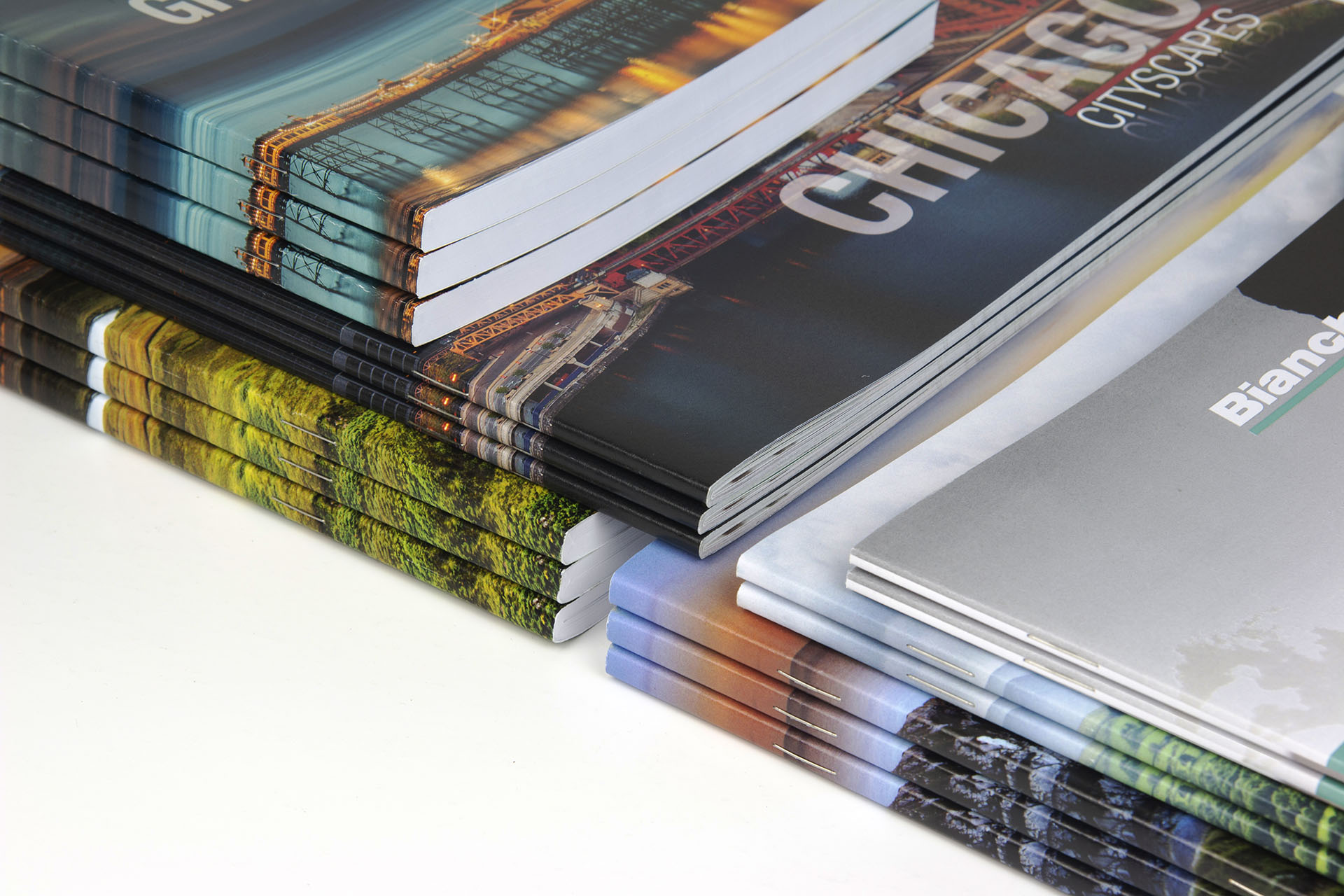

The PowerSquare Two-Knife Trimmer (P2T) is a compact module that completes the booklet making process by trimming the top and bottom edges of the book. It provides a professional solution for full-bleed printed work, especially important for colour printed applications.

Fully automated from the PowerSquare’s user interface, up to 40mm can be trimmed from each end of the book, and the trim position can be offset to match the image position. All trimmings are transported outside the machine to a high capacity external waste box, allowing continuous operation.