On the 4th of November, we had the pleasure of welcoming Australian National Print Awards winners Zaidee Jackson and Isobel Clark to our Plockmatic Group site in Milton Keynes as part of the Visual Media Association’s UK professional development tour.

Their visit followed their participation in the Power of Print Conference in London – the main event of their UK program. Representing Australia on the global stage, the two winners joined hundreds of delegates from across Europe at this annual gathering of print and paper leaders. Hosted by Two Sides UK and the British Printing Industries Federation (BPIF), the conference explores sustainability, innovation, and the evolving role of print in a digital world. The Australian delegation attended as Emerging Talent and Woman of the Year award recipients, supported by Ricoh Australia, Konica Minolta, and Plockmatic Group.

Supported by Konica Minolta, Ricoh, and Plockmatic Group, the tour gave the winners the opportunity to visit Ricoh and Konica Minolta in the UK, as well as other companies within the UK print industry.

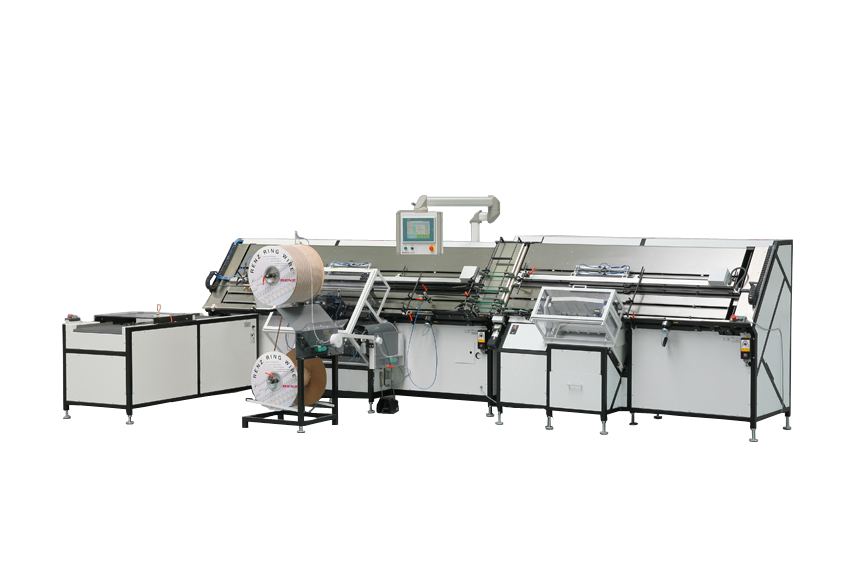

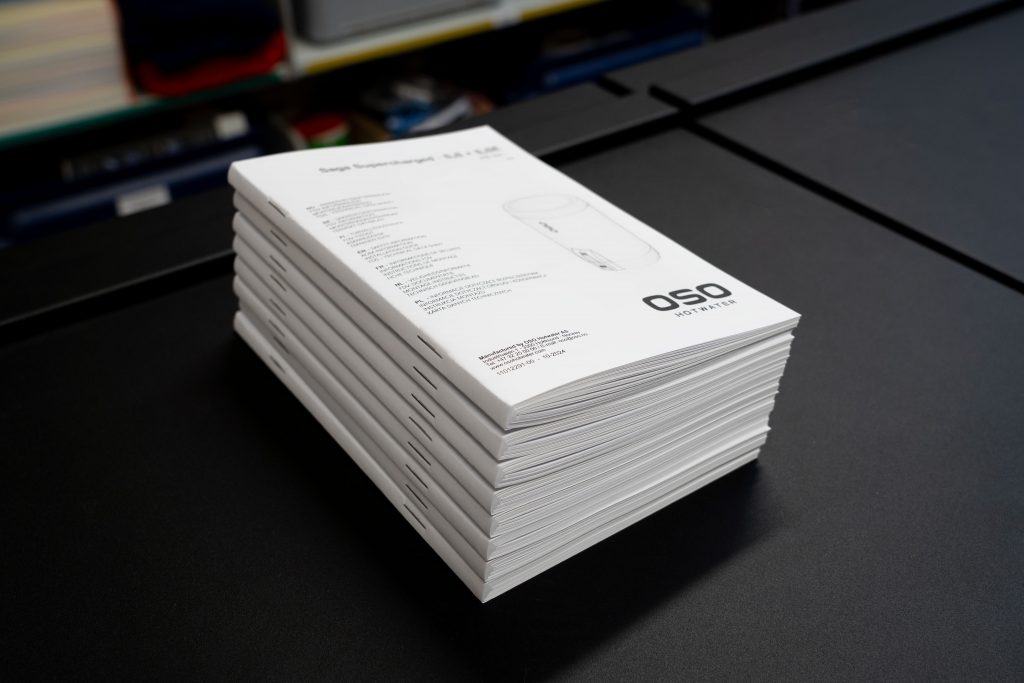

During their visit to Milton Keynes, we hosted an interactive session where the two award winners had the opportunity to explore and try out a selection of Plockmatic’s finishing solutions together with our team. Both are incredibly driven and inspiring professionals, recognised for their leadership, creativity, and strong contributions to the print community. It was a pleasure to exchange ideas and showcase our technology.

As part of the visit, Chris Toll, Regional Sales Manager – Australia/New Zealand, Asia, sat down with the winners for a recorded interview. In the discussion, they reflected on their experiences during the tour, the importance of global collaboration, the role of innovation and sustainability in the print sector, and the value of building international connections within the industry.

Hear from these two inspiring professionals as they share insights from their UK tour.

International

International United Kingdom - Morgana

United Kingdom - Morgana Baltic

Baltic Norway

Norway Sweden

Sweden USA

USA