- Region: United States +1 585 267 7692

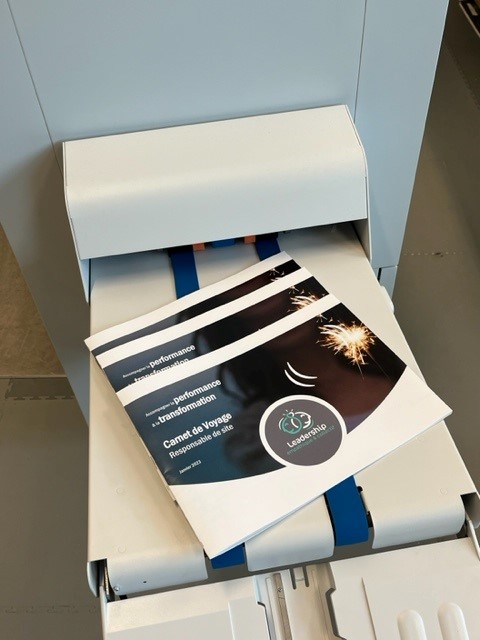

The Plockmatic BLM5050 booklet maker is installed in combination with a Canon imagePRESS C10010VP. The CRD houses one more Canon imagePRESS C10010VP with an existing Plockmatic BLM50 booklet maker, and two Canon imagePRESS C10010VP with Canon AN2 finishers. The department also includes many different types of offline equipment finishing kit, including guillotines, folders, wire binders, and glue binders.

Product Director for Sodexo, Laurent Barbut, said: “We need to produce a lot of different publications every day with our Canon print engines. It’s critical that these documents are finished correctly, even though many are very short runs.”

Senior Account Manager from Canon France, Francois-Xavier Duvernay, commenting on behalf of the print engine supplier, said: “Canon won their first deal eight years ago replacing Xerox/Horizon with Canon/Plockmatic. Since then, Canon has been the main supplier regarding professional print, wide format, software, and inline finishing. As for many in the print industry, the volumes are going down for Sodexo. Because of that they are looking for easy-to-use inline print and finishing solutions to keep print production in-house. Canon and Plockmatic has been able to provide the perfect solutions together for Sodexo so they can produce high quality booklets and other products in an easy and time saving way.”

Canon engineers work closely with Plockmatic to ensure the closest possible integration of the booklet making system with the print engine. This supports ease of use and allows operators of different skill levels to get the most out of the entire printing system.

“The new finishing unit is a great time saver. It means an overall increase in production, which gives my staff additional time to complete other tasks on the job. We are particularly impressed with the ability to finish A4 landscape publications – we couldn’t do that before.”

Speaking particularly about the latest Plockmatic addition, responsible for the production, Cyril Pioli, said: “The BLM5050 is very user friendly – and that’s one of the reasons why we chose this model. The display panel on the unit tells you exactly what to do, step by step, so it’s easy for an inexperienced operator to learn. We also have the Plockmatic BLM50 from some time ago, so we know that Plockmatic solutions are both reliable and robust.”

Laurent Barbut adds: “The new Plockmatic unit has already saved us a lot of production time and money because we can do all of the job production in-house – there’s no need to outsource anything, which is something that always comes at a higher cost.”

Overall, Cyril Pioli said: “Plockmatic deliver a reliable product, with a strong construction, that is easy to use – an ideal solution to work in tandem with our Canon printers. Whilst I do really love our French car industry, Plockmatic equipment is like comparing a Citroen to a Mercedes! It’s built so much better than other products, and it just works.”

“Because we had used a Plockmatic unit before, and we were extremely satisfied with that, we had no hesitation in returning to them again, and this time, of course, we had added extra functionality being able to produce A4 landscape books.”

With reference to future investments Pioli said: “We are always looking for new solutions to invest in – solutions that can make our business better in terms of quality or in our working environment. Special requests from our customers may require a further equipment investment, but for now we are good!”

A new kind of booklet making system that combines robust and reliable performance with a new range of applications, including landscape format. Add the Plockmatic signature square fold finish to A4 landscape format documents for the appearance of a perfect bound book. BLM5000 is available in both staple and stitch versions.

The BLM5000 series is compatible with Canon imagePRESS V1350, imagePRESS V1000 and the imagePRESS V900 series.

The staple version can handle sheets from 206 x 210mm up to 320 x 620mm, in weights from 65 to 350gsm (dependant on paper type). The maximum book thickness is 10mm (approx. 200 pages of 80gsm). The unit contains two low impact staple heads with moving clinchers.

The stitch version can handle sheets from 120 x 210mm up to 320 x 620mm, in weights from 65 to 350gsm (dependant on paper type). With RTC minimum sheet size is 148.5 x 210mm. The maximum book thickness is 10mm, dependant on paper size (approx. 200 pages of 80gsm). The unit includes two ISP stitch heads.

The company was founded in 1963. The in-house operation in Versailles, which incorporates the company’s Central Reprographics Department (CRD), came into being in 1990.

Sodexo Enterprises are one of the forty largest companies in France. They produce a wide range of products, mostly focused on food and facilities management. In the in-house print unit Sodexo produce a large variety of print on their Canon print engines that needs to be finished. Many of the print products are output from the Canon devices in booklet form, from 5 to 50 sheets in A4 format (both portrait and landscape), with most requiring a short print run – from just a couple of copies, up to 30. Approximately 80% of the work produced is for their own internal business use, with 20% of work for other companies within the Sodexo Group.

WhiteOak Printing, Lancaster, Pennsylvania (PA), USA, has become the latest printer to install a Morgana BM4050 booklet maker, manufactured by Morgana Systems Ltd, a Plockmatic International post-press product business.

The Morgana BM4000 suite of booklet makers, introduced in the third quarter of 2022, provide the finishing solution for work with low- to mid-volume digital production printers. The BM4050 delivers booklets of exceptional quality, and is able to feed long printed sheets to produce a wide variety of applications, including Letter-landscape format booklets, which are becoming increasingly popular with customers.

The new system at WhiteOak was installed and ready for action from the beginning of 2023. With regard to the arrival of the new booklet maker, Brad Kauffman, Production Manager at WhiteOak, said: “We have been familiar with Morgana equipment for some time – we have two Morgana AutoCreaser products – so when we were looking to change our existing booklet making machine, they were an obvious place for us to look.

“We found our previous unit, from another supplier, a bit of a challenge at times. The Morgana unit, in comparison, was so user friendly. The job set-up is very straightforward – you just select the size, number of pages, the desired format, the run length, and then you are all set to go. The finer detail can also be tweaked, such as the position of the folds, and the staples.

“With typical production runs of about 2,000 copies, the BM4050 just whizzes through the work, meaning that our turnaround times for jobs have been reduced. Our finishing department is just delighted with the binder.”

Work produced at WhiteOak Printing on the new booklet maker can now include the square-back finish – when a wire-stitched booklet can take on the appearance of a perfect bound product.

Typical throughput at WhiteOak includes graduation commencement programs, school sporting event programs, concert programs, manuals for construction equipment, church bulletins, and many other general commercial publications.

The Morgana Systems BM4000 series of booklet makers produce consistently high-quality booklets in a wide range of sizes and media types. The basic configuration, with hand feed capability, enables users to make booklets in an offline mode, meaning that one binder can service multiple print engines.

BM4050 can produce corner stapled documents in portrait Letter format, as well as edge stapled documents in portrait, plus the popular landscape Letter, with up to 200-page booklet capacity. The unit can also support long sheets of up to 26-inches (660mm), without the Creasing and Side slitting module (CST) or 24.5-inches (620mm) with CST.

The unit’s heavy duty staple mechanism has been designed for durability, and is maintenance free thanks to a patented solution that eliminates periodic service intervals. Users are able to adjust both the staple and fold positions through the easy initial set-up. The BM4000 series machines have a patented “set positioning mechanism” that allows the operator to adjust the staple position and direction of travel via the intuitive user interface.

Operators can now also compensate for the skew caused when feeding long sheets with a simple adjustment in the user interface, on the fly. WhiteOak can now produce SquareFold booklets in sizes from 4.1 x 5.8-inches to Letter-sized Landscape, or the Letter-square and even the largest 11.96″ x 11.96″ format.

Established in 1984 this locally owned business began life in Marietta, Pennsylvania. In 1987 the business moved to downtown Lancaster, and then in the next decade, 1995 to be exact, the company moved into its present day 18,000 square-foot building in Dillerville Road, Lancaster. In 2001 the company installed its first digital colour press – an Indigo UltraStream. In 2004 the business created its own online ordering system. By 2012 the business was ready for growth, and it acquired the promotional products company, GPI Marketing, and the growth continued the following year when it acquired another promotional company, Creative Promotions Plus. Print growth continued, and in 2021the latest and greatest piece of equipment, an HP Indigo 12000 was installed.

John Brailsford Printers, “Yorkshire’s Favourite, Fast, Friendly Quick Printer!”, has become the first UK print business to install a Morgana ColorCut SC6000 digital die-cutting and creasing machine. Morgana Systems Ltd, Milton Keynes, a Plockmatic International post-press product business, debuted the product earlier this year at the Hunkeler Innovation Days.

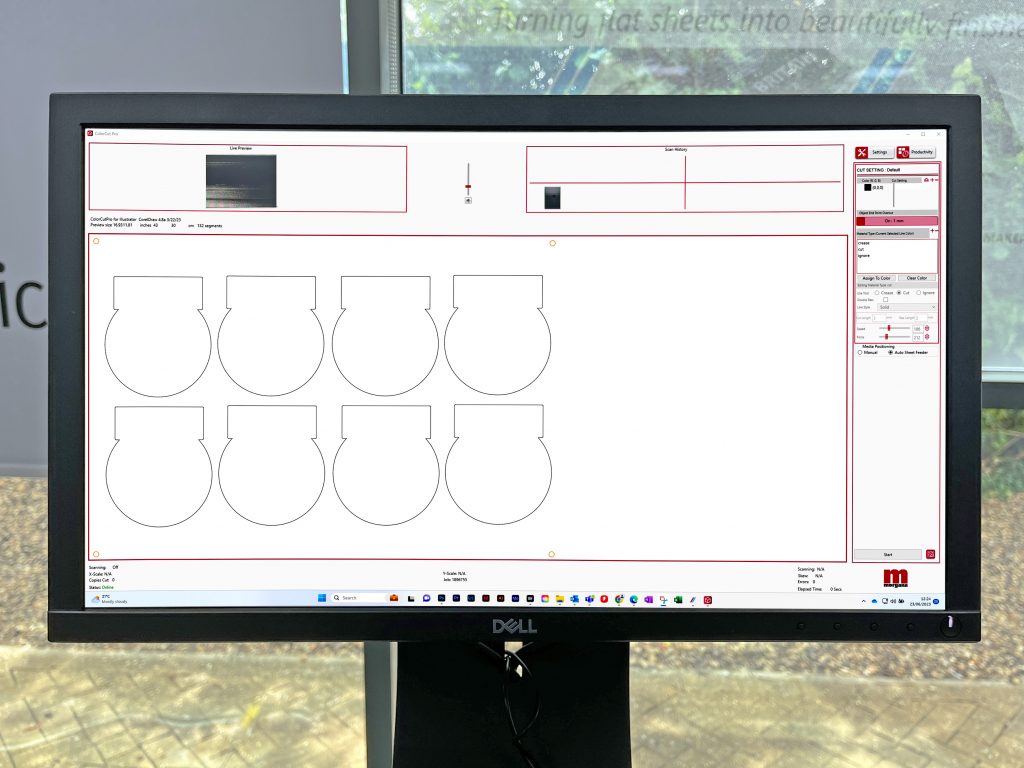

ColorCut SC6000 is a freestanding, “on-demand” digital sheet cutter and creaser, with no physical cutting dies or time-consuming set-up costs. The unit is targeted at busy print businesses seeking an affordable, high-capacity device, capable of completely unattended cutting production. The compact, free-standing device is conveniently mobile, and can be easily accommodated in any print shop. It is ideal for the production of labels, stickers, display materials, short run packaging work, and other “any shape” cut-out jobs.

John Brailsford Printers, the Rotherham shop-fronted business, had reviewed a number of potential products in the cutting and creasing sector, but nothing quite fitted the bill.

Commenting on this sector of the market, John Brailsford, company owner, said:

“We had looked at a variety of potential solutions, but nothing was quite suited to our needs. Either they were too expensive, were overly complex, or they still needed dies to be produced. The previous Intec machine, the SC5000 was close, but not quite large enough to handle the range of stock that we needed to process. We thought we were just going to have to stick to outsourcing any work that required die-cutting.”

“We could see that digital die-cutting was definitely the way to go – then we had a call from Ray Hillhouse of Morgana, who said to me, “I’ve got just the machine for you!” We have a long history of working both with Ray and with Morgana. He knows us well, and he knew exactly what we needed – and the SC6000 was introduced to us.”

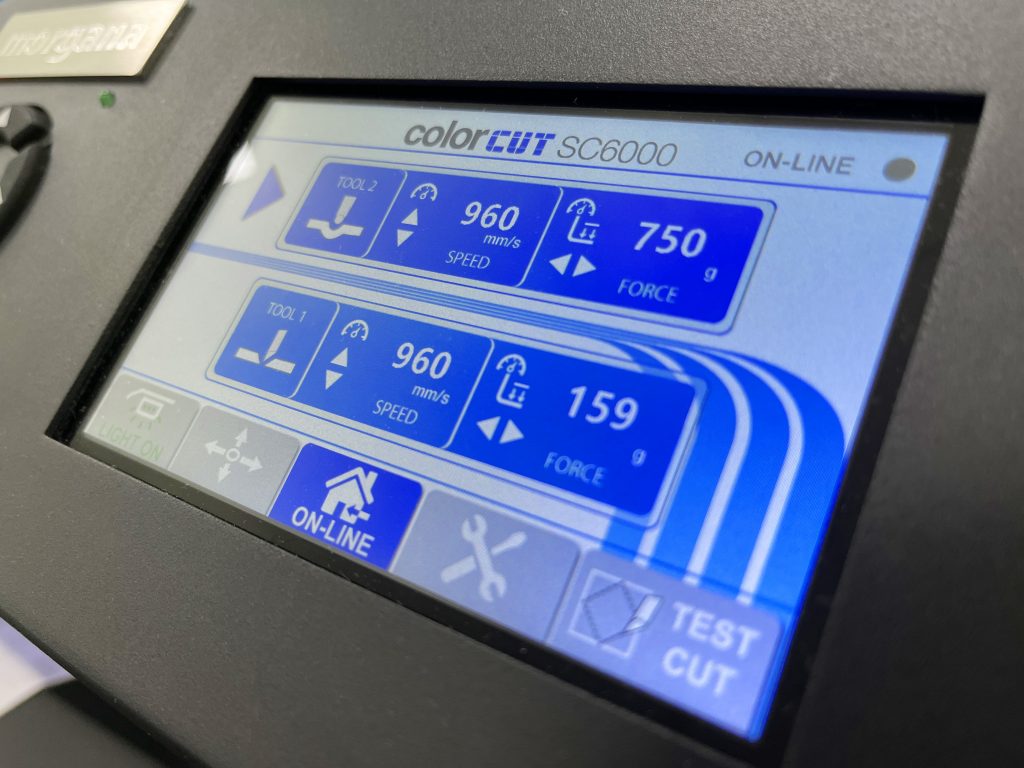

The Morgana ColorCut SC6000 is a revolutionary type of automated cutter, blending flatbed and sheet fed technologies, with a maximum working area of 340 x 710mm / 13.4″ x 30″. The SC6000 combines ultra-reliable feeding with an instant job retrieval system, and flawless high-speed cutting and creasing. This model is the new “bigger brother” of the highly successful Intec ColorCut SC5000, with a range of updated features.

“We introduced the SC6000 to our studio people initially. They are the techie people who deal with files in our pre-press. They were able to easily understand the “front-end” of the machine. The output from the studio, including cutting requirements and run length, is encapsulated in a QR code, meaning that all the people at the post-press end of the factory need to concern themselves with is selecting the right stock and scanning the QR code printed on the job.”

“This machine is quite amazing. The results have been quite superb. We keep thinking up new ways of using it – with labels, for example, we are now running through our stock of pre-cut labels, and then we can simply use the SC6000 to kiss-cut the labels for us on plain adhesive-backed stock. That means any sized, or shaped, self-adhesive label is possible, and we don’t need to have the expense of holding any stock of various sized at all.”

“Another area where we realised that the machine could help us: dividers. We produce these for a number of customers. Dividers, to go into work books, or educational folders. We can have the SC6000 cut-out the card for the tab, and even cut the holes for the binders at the same time. It’s not necessarily faster, but we can set the machine to produce these dividers and it will just run, while the operator gets on with other jobs,” added John.

The digital cutting head can apply up to 750g of force, individually, for both the cutting and creasing tools. Their actions are controlled via the ColorCut Pro software, which is included in the purchase. In common with the entire ColorCut family, the SC6000 can be set to apply exact amounts of pressure and speed, along with total control over the application of cut, crease and perforation of the vector artwork lines.

Focussing on the feeder on the ColorCut SC6000, John was extremely impressed: “The feeder is a critical element for such a machine, and this one is amazing! It will feed virtually any stock, it seems, eliminating any static issues, and the potential for any doubles.”

“We had been sending work such as short run boxes, pocket folders, and various other cut-outs, to an external supplier. That kind of work has definitely been on the increase, so this really was the right time for us to bring such tasks in-house – it’s going to cut our outwork bill significantly, and therefore will pay for itself in no time.” The company has been using plastic boxes for the delivery of business cards to customers. Now they are producing cardboard boxes with the help of the SC6000 – more convenient and better for the environment.

A revolutionary cutting strip, based on the superior cutting mats used in Intec flatbeds, provides for an optimal surface for both cut-through, creasing, and kiss-cut. SmartTags are left in the cut lines to retain the job information on the sheet, leaving a tidy and manageable stack of finished sheets in the catch tray.

Ray Hillhouse, Plockmatic VP of Sales & Marketing, said: “The ColorCut 6000 is going to be a very popular product for the small to medium sized print business. Everywhere we’ve shown it printers have been excited about what it can do for them – and the more they think about the machine and its potential, like John and his team, the more new ideas they are coming up with. That simple process must make the justification for making a purchase of the machine a very straightforward process! I can easily see the SC6000 being our most successful product.”

Morgana says that particular attention has been paid to the feeding system to ensure class-leading performance for card, vinyl labels, or even tricky laminated sheets. The SC6000’s auto feeder accepts up to 900 sheets, raising or lowering as required. To prevent sheets curl, a constant air flow to the sides of the stack is used. The SC6000 uses an automatic air blade that fires a blast of air momentarily into the front of the stack, just as the advanced vacuum feed belt lowers to collect the top sheet using pneumatic suction. To further provide a reliable feed, the vacuum feed belt lifts the media, carrying any sheets not pre-separated by the air blade past a pair of dexterous separation fingers to dislodge them. Finally, before advancing the sheet into the cutting engine, the vacuum feed belt jogs briefly against the rear paper stop, creating a natural curve that helps ensure even difficult media can be fed faultlessly.

SC6000 will cut and crease virtually any shape on up to 350-micron media, including kiss-cut sheet labels. A QR code, via the job library, retrieves the associated cut files, even for a mixed batch of jobs in the same run. The Morgana ColorCut SC6000 is perfect for digitally die-cutting packaging and point-of-sale items, as well as lightweight card projects, and labels. The expanded size of the unit will be of great appeal to those producing larger format work, such as display signage.

“Keeping control of the delivery of work, as well as keeping the margin that would have been lost by sending work out – these are the critical factors that printers tell us frequently when purchasing this type of product.”

About John Brailsford Printers

It was 37 years ago that John Brailsford, 16 years old at the time, produced his first print job. The local commercial printers could not compete with the super quick turnaround, the great choice, and value for money that John Brailsford Printers provided and even today the company is proud to say that it still leads the way in offering customers, sharp, crisp quick printing, and digital imaging, with a professional unbeatable, super friendly customer service that has to be the best value in Yorkshire.

More than just a regular quick printer, the company has 12 experienced and qualified employees, coupled with the very best mix of the latest litho and digital equipment. The business runs two Presstek offset litho machines as well as Xerox digital printing equipment, from its print centre in Rotherham.

For more information visit the BrailsfordPrinters.com web site.

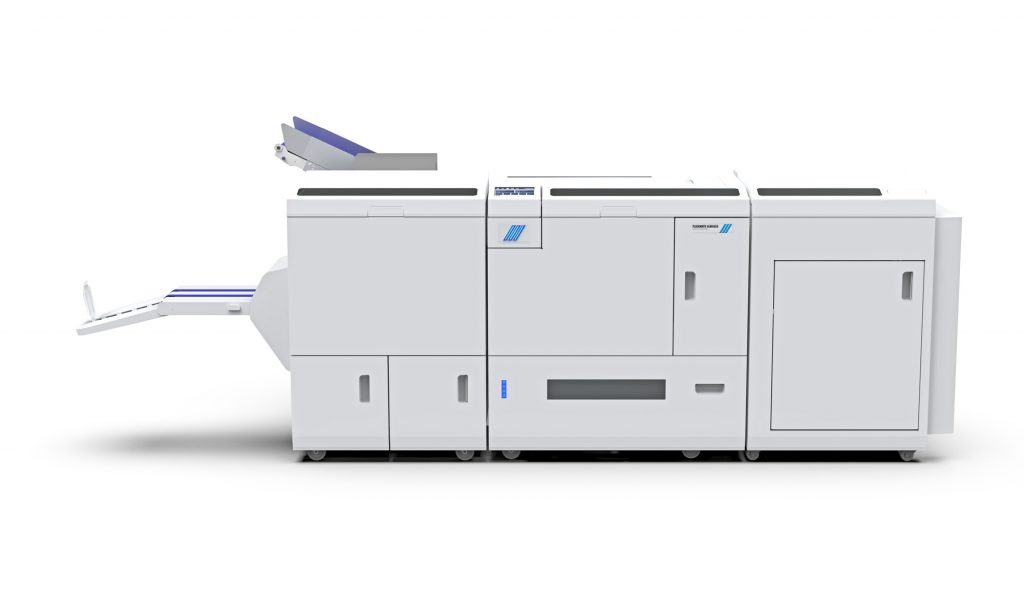

Plockmatic International, Sweden, announces the release of its BLM5000 series production booklet maker for inline integration with Canon’s imagePRESS V1000 and V1350 digital toner presses.

Designed for customers with mid- to high-production volumes, the device offers the scope to produce A4 and “letter” landscape format booklets, in addition to regular sized, portrait format booklets. It allows for square-back folding and full-bleed three-side-trimming to remove feathering on the outside edge from folding multiple nested sheets. Available with staple or stitcher heads in 50- or 35-sheet versions, the BLM5000 will extend the application capabilities of print businesses, especially those producing long-sheet “banner” prints with the imagePRESS. The stitcher unit can include two to four ISP stitch heads. The new range of applications include landscape format, with jobs two-up and more.

Whilst the BLM5000 can be installed inline with a Canon printer, it can also be supplied with an optional Plockmatic VFX feeder to create an offline or nearline configuration. The VFX is a high-capacity Vacuum Feeder capable of efficiently feeding a wide range of paper types and weights, with speeds of up to 15,000 sheets per hour.

The BLM5000 booklet maker joins the Plockmatic BLM 550+ and BLM 50/35 systems among the range of high-performance third-party finishing devices offered by Canon, enabling the creation of tailored and highly automated end-to-end production solutions. The integration of these systems also allows print service providers to produce a broader application mix, generating more business growth opportunities.

“We are really excited to expand and solidify our business relationship with Canon adding the new BLM5000-series into our joint portfolio of solutions offered to customers. The BLM5000-series will broaden the offerings to customers allowing for a wider range of applications and drive volumes for the printing community. Fulfilment is more important than ever – allowing for printers to provide end-to-end solutions to their customers and with the launch of the BLM5000-series more finishing options are available and adding to the business opportunities”, says Johan Mikaelsson, VP Business Unit Inline, Plockmatic Group.

Jennifer Kolloczek, European Planning, Marketing & Innovation Senior Director, Production Print at Canon Europe commented:

“Our digital print customers continue to look for new ways to produce professional-looking documents at shorter run lengths, while maintaining or increasing profitability and productivity. This calls for more seamless end-to-end workflows, making cost-effective inline finishing solutions a critical success factor. The latest Canon imagePRESS production printing systems can manage an unprecedented range of substrates and sheet sizes, while delivering exceptional image quality levels, so we’re pleased to be able to offer a productive and reliable booklet maker that is equipped for our customers’ production demands.”

The BLM5000 series is available via Canon sales offices throughout EMEA, for inline configuration with an imagePRESS V1000 or V1350. Four stitch-head configuration, 50-sheet option for stitcher version, and offline configuration are not available in EMEA region.

The BLM5000 series is available via Canon sales offices throughout US, for inline or offline configuration with an imagePRESS V1000. V1350 support will be confirmed in the future.

Plockmatic Group, one of the world’s leading developers and manufacturers of document finishing technology, has acquired Intec Printing Solutions Ltd, headquartered in Poole, Dorset, a major global supplier of unique equipment solutions for the print and graphic arts markets.

The current star of Intec’s product line-up is the company’s ColorCut range, which includes entry-level large-format production flatbed cutting products. Additionally, Intec offers the ColorFlare range of desktop and professional devices to enhance prints with both foils and laminates.

The company is now a wholly owned subsidiary of Plockmatic International AB and part of the Plockmatic Group, which includes the well-known Morgana and Watkiss ranges of offline finishing systems. The Swedish firm’s CEO, Jan Marstorp, will continue to head the expanded group of companies.

Commenting on the acquisition, Jan Marstorp said: “Intec are well known in the industry for providing quality products at competitive prices. The ColorCut range of cutting systems have been well received by the market, with sales in the UK, across North America, and many other international territories.

“These systems are ideal for small to medium sized print-based operations that need to provide professionally cut and finished promotional display boards, boxes, labels and more. This is a sector of the market that has grown rapidly in recent years, and one that Plockmatic is keen to further explore and expand.

“We also see a good match for these products with our large OEM customers who provide printers. These products will enable more applications and allow them to grow further into the light packaging and labelling market segment.”

With regard as to how these products fit within the current range, Ray Hillhouse, VP Sales & Marketing for Plockmatic’s Offline Business Unit adds: “Our UK Morgana sales team have enjoyed considerable success with the Valiani range of large format finishing systems in recent years. We see the ColorCut suite of products complementing these in the UK and providing a terrific opportunity in this expanding market segment for our international dealerships worldwide.”

The Plockmatic company will seek to expand sales of these devices through the existing Intec & Morgana international dealer networks, Plockmatic’s OEM partners as well as through its subsidiary operations in the UK and USA. Intec Printing Solutions will continue to design and configure products at its Poole headquarters, and all current staff will be retained. The acquisition includes the company’s US operation, Intec Printing Solutions Inc., based in Tampa, Florida.

The Intec business was founded by Ian Melville back in 1989. Commenting on the sale to Plockmatic International, Ian said: “Having started the business focussing on Apple Macs and pre-press products back in 1989, we’ve travelled right through the printing process to our current range of post-press equipment. I can safely say that it has been a long, eventful, highly enjoyable, and, ultimately, very successful journey. It has been a great delight to meet with printers and print equipment suppliers from all around the world – they are all great people. It has been a pleasure to be a part of this fantastic and highly adaptable industry.

“As the owner of a successful business there comes a time when the question of where the business goes after I’m gone has to be posed. The sale of the business to Plockmatic has come at a good time for me, for Intec Printing Solutions, and for my fantastic team. This transaction will give me the opportunity to spend more time on several charitable projects that I have been involved with, as well as enjoying some well-earned holiday time. For the business and the staff, it will provide the solid backing from a successful international manufacturer.”

The Plockmatic Group of companies is part of Grimaldi Industri Group, a diversified Stockholm-based holding company. “The acquisition of Intec Printing Solutions further demonstrates our commitment to our customers, and to the document finishing business,” says Salvatore Grimaldi, owner and CEO of Grimaldi Industri.