- Region: International

Business owner Tony Cordova (shown right) explained the need for his busy print shop: “The purchase of our DigiFold Pro was driven by the need to score digitally printed materials in-house and improve our folding capability.”

The DigiFold Pro is Morgana’s easy to use, stand-alone, folding and creasing machine. The product has been one of the company’s best sellers since first introduced back in 2001. Morgana DigiFold Pro employs a unique creasing rule and matrix, the DynaCrease, which creases without stopping the sheet giving the highest possible production speeds.

The DigiFold Pro at ARC has replaced a Baum 714 folder, along with the outsourcing of scoring requirements. The benefits of having such a capability in-house are big from a cost perspective, but the time saved from not outsourcing such a task is an even bigger plus for the ARC team.

With regard to the purchase decision Tony said: “We considered all of the different product offerings and concluded that the combination of quality scoring and folding in one device from Morgana provided the versatility we needed.

“On top of that, it’s all about ease of use, along with capability and speed. Most importantly, this purchase has allowed us to reduce our dependence on outsourcing for scoring services and allowed us to turn jobs around quicker, meaning a faster delivery to our customers.”

Tony Cordova is also delighted with the performance of his latest purchase: “The DigiFold Pro has operated for us with consistency and minimal maintenance. The quality of this device along with performance has generated a confidence for us in Morgana products. We would not hesitate to purchase Morgana products in the future because their quality, performance, and dependability are already proven.”

Despite the efforts of competitors, the DigiFold Pro is still the market leader in its sector and the product of choice for a great many digital printing professionals. The patented creasing technology sets this machine apart from the rest, still giving it an edge in the world of finishing for digital print.

The product can be used as an integrated creaser/folder, performing both functions in one pass; as a stand-alone creaser when folding is not required; or as a perforator when this finish is required.

A maximum sheet size of 27.5″ x 15″ (35.4″ x 15″ with optional extension table) allows for a wide range of jobs to be produced. Morgana has managed to increase throughput speed to over 6,000 A4 sheets/hour, yet maintaining an accuracy of +/- 0.1mm.

The impending arrival of a child led to Tony and Ruby Cordova to take the extensive knowledge that they had gained in the packaging industry and make that huge leap of faith in opening their own business. In 2001 they opened their own printing company, ARC Impressions in north Phoenix – the name simply reflects their own initials.

From its inception, Tony and Ruby wanted customers to receive the best value. They wanted their clients to know they could rely on ARC for advice and guidance on how each project could best be created to meet budgets, visual appeal, worry-free production, and on-time delivery.

To truly meet clients’ needs meant ordering one-stop processes, and ARC has built a business that focuses on problem-solving and seamless production. Along the way, Tony developed ARC’s packaging production capabilities, working with his manufacturing contacts around the country. With their daughter, Alexis, now grown, Tony is often traveling to packaging vendors to ensure every step goes smoothly.

For more detail visit www.arcimpressions.com

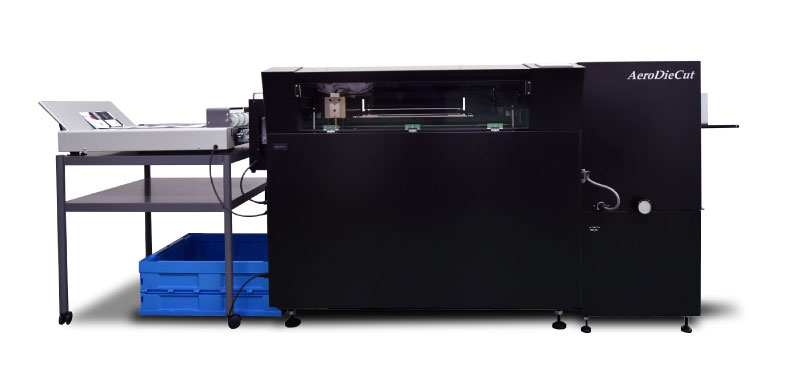

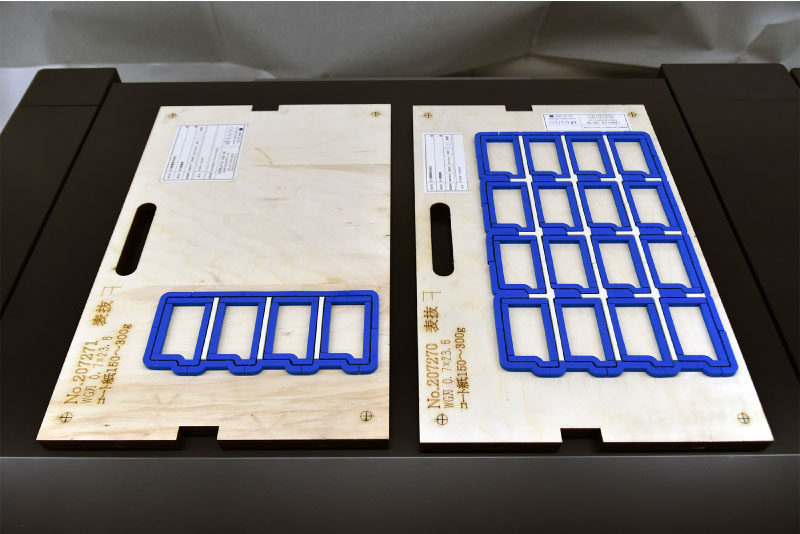

Lithuania based Artrema have chosen to invest in the new AeroDieCut for the production of small medical packaging. Having previously been using a Heidelberg cylinder made in the sixties for their cutting and creasing applications, the requirement to produce small run medical packaging has led to the AeroDieCut becoming the latest addition to their itinerary.

Although the Heidelberg cylinder is a highly capable machine, the AeroDieCut has a number of advantages over the 1960s technology, the main advantage being that it can cut, crease, and emboss / deboss all in one pass. This is ideal when producing medical packaging, where the use of braile is a legal requirement under European law. Adding to this, the device is easy to setup and removes the need of a skilled operator, and offers a much lower risk to health and safety. With all features it’s easy to see why the AeroDieCut is the obvious choice for future production.

Another advantage is that despite the improvements to die cutting technology, the AeroDieCut still utilizes traditional platen dies, which over the years have proven to be a reliable, easy to obtain and cost effective solution, producing a very high quality, professional finish.

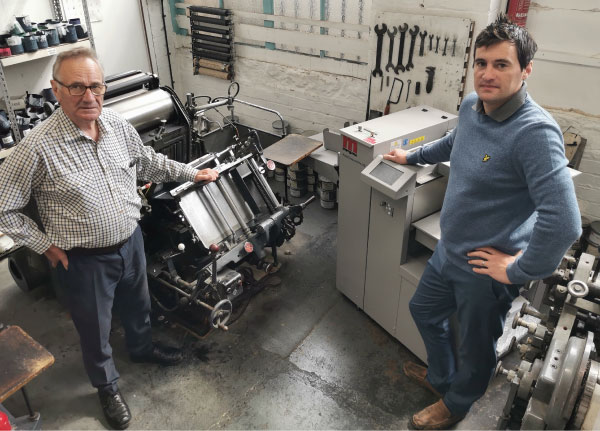

Richardson & Son, based in Hawick in the Scottish Borders, has invested in a Morgana AutoCreaser Pro XL, purchased through Morgana dealer CLC.

Commenting on the need for the AutoCreaser Pro XL, Jamie Richardson, Co-Director, said:

“We do a lot of creasing and perforating on our Thomson Platen machines, but it takes quite a bit of skill and time to make-ready those machines. A lot of the jobs we do are small runs, like sock bands and swing tags, for example, so make-ready was taking longer than the time to actually produce the work.”

“One of the team had seen something about more automated creasing products online, so we made enquiries to three of our print finishing equipment suppliers. All of them came back with the same answer – that the Morgana AutoCreaser Pro XL would be able to handle our needs. We knew the Morgana team, as we have a few other Morgana machines on-site, so then, because of our location, we needed to find the best service solution as well as the best price. Although pricing was pretty close between them all, CLC offered an on-site demo, so in the end we went with them.”

Would this new arrival make the existing trusty platen products redundant? “No, we’ve kept the platens, and our Titan cylinder. Although the Titan will probably never run again, we are not really short of space, and it is an impressive bit of kit – also I guess we could be a little sentimental. The platens though are still used for die-cutting, and creasing heavier stock on a regular basis.”

The Morgana AutoCreaser Pro XL paper creasing system is an easy-to-use product with a highly efficient vacuum top feeder. The unique creasing rule in the AutoCreaser Pro XL eliminates paper tearing and, therefore, cracking. The Pro XL runs at a maximum of 8,500 A4 sheets per hour, with no loss of accuracy.

The product is Morgana’s most productive creaser to date, complete with the ability to handle longer sheets. The new AutoCreaser Pro XL takes a sheet size of up to 385 x 1,300mm with the table extension. Its feeder boasts an ultrasonic double sheet detection, an inline rotary perforation system with the capacity for up to five perforations at the same time, as well as the option of a cross perforation unit.

“The machine has done a lot of varied tasks. It perforates our raffle tickets, creases menus, order of service sheets, greeting cards, sock bands, swing tickets, and many more. The biggest plus, of course, is the make-ready time between jobs – it’s just so quick and simple. The machine runs every day, doing a variety of different jobs, and has definitely helped us increase our productivity.”

About Richardson & Sons

Richardson & Sons is a family run business based in Hawick, Scottish Borders. Established in 1946 by Jimmy “The Printer” Richardson, the company started out from premises at Dovemount Place and remained there until 2001 when it moved to the old Hawick News building, Lochpark Industrial Estate. From here it continues to offer a range of professional printing and finishing services to the public and the trade. The running of the business continued with Murray Richardson taking over when his father retired, and is now run by Murray, his wife Ebie, and their son Jamie. The business has grown from strength-to-strength with three other employees: David Finnie, our printer, who has worked with us for over 40 years; Robert Scott, our graphic designer and pre-press operator; and Christine Rodger, our secretary and book keeper.

For more information, see richardsonprinters.com

Jossimo Print t/a MinuteMan Press

“I love talking Plockmatic!” – Simon Crabtree, Owner MMP Melbourne locations Simon is the owner of three Minuteman Press locations in Melbourne; Knox, Glen Waverly and Hawthorn. We recently had a chat about his business and where Plockmatic has been an important chapter in his story. I was also able to spend some time talking to his production manager Mel Shilland, who has worked for Simon for the past 9 years.

The reason I wanted to talk to Simon was that he has been a long-time user of the Plockmatic range and as he states, “Plockmatic got us started, and helped us grow”. I have worked with Simon for many years and after having this discussion I came away with a better understanding of the breadth of his business and how Plockmatic has played such an integral role.

Simon did not come from traditional print, but rather the call centre industry. He came into the MMP franchise with a fresh sense of wonder and a keen drive to succeed. The first store for Simon opened in 2009 at Glen Waverly. Here he got into his first Plockmatic BM2000 in 2012 configured with a 510ACF collator/ feeder. He added a BM2000S stitch head model in 2014. He still uses that system today for many booklet jobs.

In 2015, Simon added the Knox location to his franchise bailiwick. This also was where Simon added a Fuji Xerox C800 with Plockmatic Pro50, their Kirst Plockmatic inline bookletmaker. Mel tells me, “inline bookletmaking changed my world!” This gave them the opportunity to produce books at printer speed and deliver to the customer sooner while saving two hours of binding time.

In 2016, another FX printer was added, this time the C1000 with a Pro50 inline. However, the BM2000S was still used for jobs that were printed on other sources or needed to be combined with other print. Even though the 510ACF can feed pre-collated sets, they have found that their workflow works best as individual sheets. Meaning, they print all the pages, then load the 510ACF to collate the sets into the BM2000S.

In 2017, Simon adds the Hawthorn location as a satellite store and purchases a KM1 press for the Glen Waverly store. The B2 sheet size meant much of the bookletmaking needed to be done offline. Most of that work goes into a new Horizon Stitchliner, but the BM2000S still takes on many offline bookletmaking jobs.

And last year he added some Ricoh printers to the mix, one of them a 9210 with inline PBM500. As with the Pro50’s, Mel and her team Kind that inline bookletmaking offers the ability to produce books as they print. This saves time and cost, providing the customer with a quality booklet on demand. The Plockmatic SquareFold process has also given these MinuteMan Press stores the difference in the market to stand out. “I love SquareFold, it is absolutely amazing!”, is what Mel tells me. Producing books with SquareFold gives a perfect bound look for a fraction of the cost and time. It also allows for printing on the spine and easy handling when the books are complete.

With so many options to produce print within the group, the hand feed capability of the PBM500 has been beneficial. During my visit to review the operation, I witnessed the operators running the Ricoh 9210 with PBM500 at the same time hand feeding a booklet job with cover that had a fold out on the inside of the cover. This job would be difficult on many finishers, but easily produced by the unique function of the hand feed on the Plockmatic inline bookletmaker.

Producing over 15,000 books per month keeps Simon and his team quite busy. Typical applications range from Marketing brochures to perfect bound novels. The substrate range is from 80-350 gsm, however most jobs would have 128gsm body stock and a 300gsm cover. The benefit of the 50-sheet version of the inline Plockmatic bookletmaker is the ability to easily bind stocks of heavier weight, including textured substrates. Many books that may have been traditionally done by perfect binding, can now be done at the same time as printed with the PBM500.

At the time of this publication, Simon was looking at the Plockmatic BM5050s, our newest addition to the bookletmaking stable. This model is an industry first, able to produce landscape A4 books up to 50 sheets with up to 4 stitch heads. One of the reasons this model is attractive to Simon, is that the Horizon Stitchliner that is capable of making landscape A4, cannot produce SquareFold books. Since Simon’s teams typically produce SquareFold on the many Plockmatic devices, their customers have become accustomed to the quality finish and expect it on all jobs they produce. In the meantime, Simon has added an offline Plockmatic BM500 with vacuum feeder and an additional Ricoh printer with PBM500 inline. Plockmatic is happy to be part of their success!

Snap Melbourne

Snap Little Collins St in Melbourne is owned and operated by Michael Waugh and this Case Study presents his experience with the new Plockmatic SD500 inline booklet maker and how it has helped his business grow. Michael has owned the 18 year old store for the last 8 years. They specialise in onsite digital print and finishing along with wide format and graphic design. One can also get offset print done through this Snap location but the jobs are outsourced. The main operator, Jarrod enjoys the ease of use of the SD500 along with the increased productivity.

Equipment

Michael has another printer equipped with an inline bookletmaker, but it is one that does not keep up with productivity nor does it have full bleed trimming. So prior to installing the SD500 Plockmatic inline bookletmaker on his new KM printer, all of the booklet work was slower and required another offline process to trim the head and foot of the book on the guillotine. Also on hand is a digital creaser/folder and Renz book binding equipment. The SD500 with Rotate Crease and Trim capability allows for full-bleed booklets to be produced at printer speed with no additional operator.

Application

Most of the books produced through the SD500 are corporate brochures and booklets on 80gsm text with a 350gsm cover. At 150-250 books per job and averaging 15,000 books per month, the SD500 keeps up easily with the productivity.

Michael’s impression of the machine is that he loves it since it has saved him and his team time and effort. One improvement he would like to see is a better way to handle trim waste from the side trimmer. I was able to direct him to the Plockmatic Trim Waste Conveyor, that would help him keep the booklet maker productive.

Michael mentioned that the SD500 has not missed a beat and has resulted in quite an advantage in the market due to better lead times and a quality, professional book. The other benefit of the SD500 with 200 page booklet capacity, is the number of jobs that used to be perfect bound that now can be produced inline at a lower cost. Perfect binding requires a set up fee plus a premium charge over stapled booklets. However, since the capacity of the SD500 is up to 50 sheets of paper, many jobs that typically require perfect binding can now be run inline at printer speed at no extra labour or time.