- Region: United States

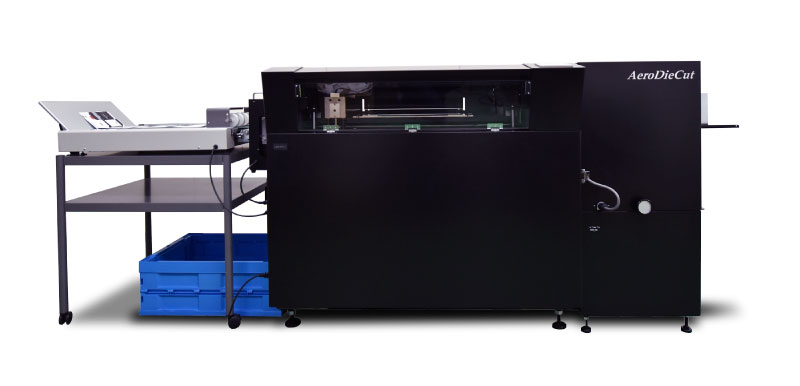

The Morgana AeroDieCut gives printers and marketing services an innovative solution for cutting, creasing, debossing and perforating. Whether it’s for unique shaped cards or packaging or labels, printed items can be processed much faster, than traditional methods personalized, with more versatility and economy on production runs.

The AeroDieCut is easier to use than traditional large format die cutters and more productive than cutting plotters and laser cutters. The AeroDieCut can process complex cuts, creases, and perforations on printed materials in a single pass.

▪ Labels

▪ Tear off vouchers

▪ Business cards

▪ Greeting cards

▪ Postcards

▪ Tickets

▪ Playing Cards

▪ Boxes

▪ Personalised packaging items

In the past, die cutters were large, heavy duty devices, and could be used for decades, but they required skilled operators. The AeroDieCut was designed to be used by anyone, anywhere, with a focus on operator safety and minimal mechanical adjustments.

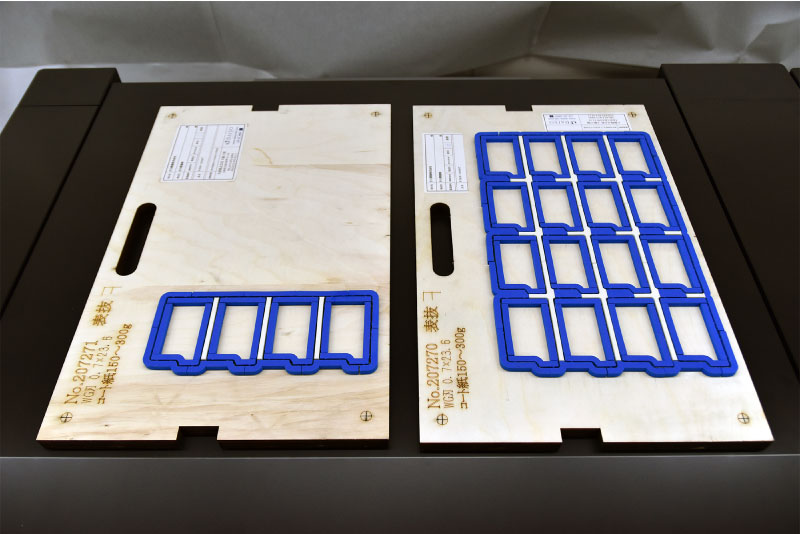

The AeroDieCut utilizes traditional platen dies which are tried and tested, easy to obtain, cost effective and the quality of the finishing is great.

The AeroDieCut turns your printed materials into a variety of applications such as cards, boxes, swing tags, shelf talkers, etc. Combining both traditional and new technologies, the AeroDieCut can transform your creative ideas into reality, enabling your business to grow.

The main press unit uses patented “moving press rollers” mechanism to press the paper. This makes the die cutting process much quieter and efficient than most conventional die cutters.

The patented “Tri-suction feeder” ensures consistent paper feeding. The feeding unit equips an ultra-sonic sensor for double feed detection, and a cut-mark sensor to compensate image shift.

The optional separator deflects wastes into a waste bin as the die-cut paper is delivered (Depending on layout). The optional conveyor delivery table makes the collecting process more efficient.

The AeroDieCut features a step and repeat function to finish multiple-up applications, this saves the cost of multiple dies.