- Region: Baltic +371 67 114 013

The Morgana PowerSquare™ 160 booklet making system for Konica Minolta meets the needs of mid to high volume printers, capable of producing A4 / 8.5” x 11” landscape books. The machine is configured with one or two precise and reliable vacuum feeders, each with a 270mm / 10.6” capacity. OMR is standard, with optional barcode readers. Finishing your print jobs offline gives you flexibility in your workflow and handles the output from multiple digital engines.

The PowerSquare™ 160 is a modular open-architecture system that is flexible and versatile: it lets you produce booklets from a wide range of sheet sizes and materials, including A4 landscape format and heavy cover stocks. With optional accessories for full bleed trimming and book stacking, enabling you to increase productivity and efficiency.

Hand feeding is often the most practical solution for low volume digital printed jobs, where ease of set-up along with flexible media sizes are important. Book quality is never a compromise with the fully featured Hand fed PowerSquare™ 160. This model is designed with an easy upgrade path to add feeders or operate inline to your printer.

The PowerSquare Two-Knife Trimmer (P2T) is a compact module that completes the booklet making process by trimming the top and bottom edges of the book. It provides a professional solution for full-bleed printed work, especially important for colour printed applications.

Fully automated from the PowerSquare’s user interface, up to 40mm can be trimmed from each end of the book, and the trim position can be offset to match the image position. All trimmings are transported outside the machine to a high capacity external waste box, allowing continuous operation.

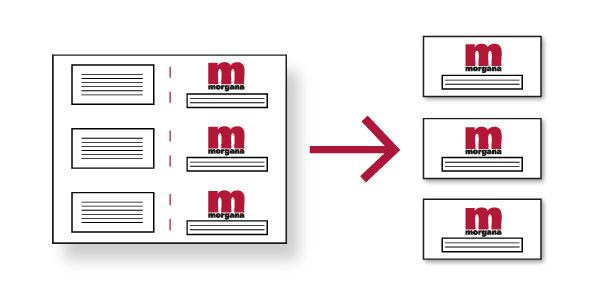

The PowerSquare 160 now has the capability to apply up to six staples per book. Making it possible to run smaller applications 2 or 3up on a set, saving valuable time and money.