- Region: Norway +47 23898586

If you are looking for digital cutting then look no further. Visit us at FESPA – Stand A45 Hall 4.2, to see the latest digital cutting solutions for short run, personalised packaging, kiss cut labels plus much more… so Relax, the possibilities are endless!

To register for the event and get discounted tickets go HERE

Please make sure you save the date for our great NorthPrint & Finish event on Wednesday 5th and Thursday 6th March 2025 at the Manor Golf Club, Drighlington, Bradford, BD11 1AB .

Watch out for your personal invite next week. We will be showing our range of digital cutting equipment, our marketing leading DigiFold Pro XL folding and creasing machine, and the BM4050 booklet maker – plus lots more!

If you don’t want to wait for your personal invite – you can register here

NPC Print, Mytchett, near Camberley, Surrey, has upgraded its booklet making capability with the purchase of a Morgana BM4035. The new finishing device replaces a previous Morgana booklet maker. The BM4035 expands the range of sizes and formats that can be produced.

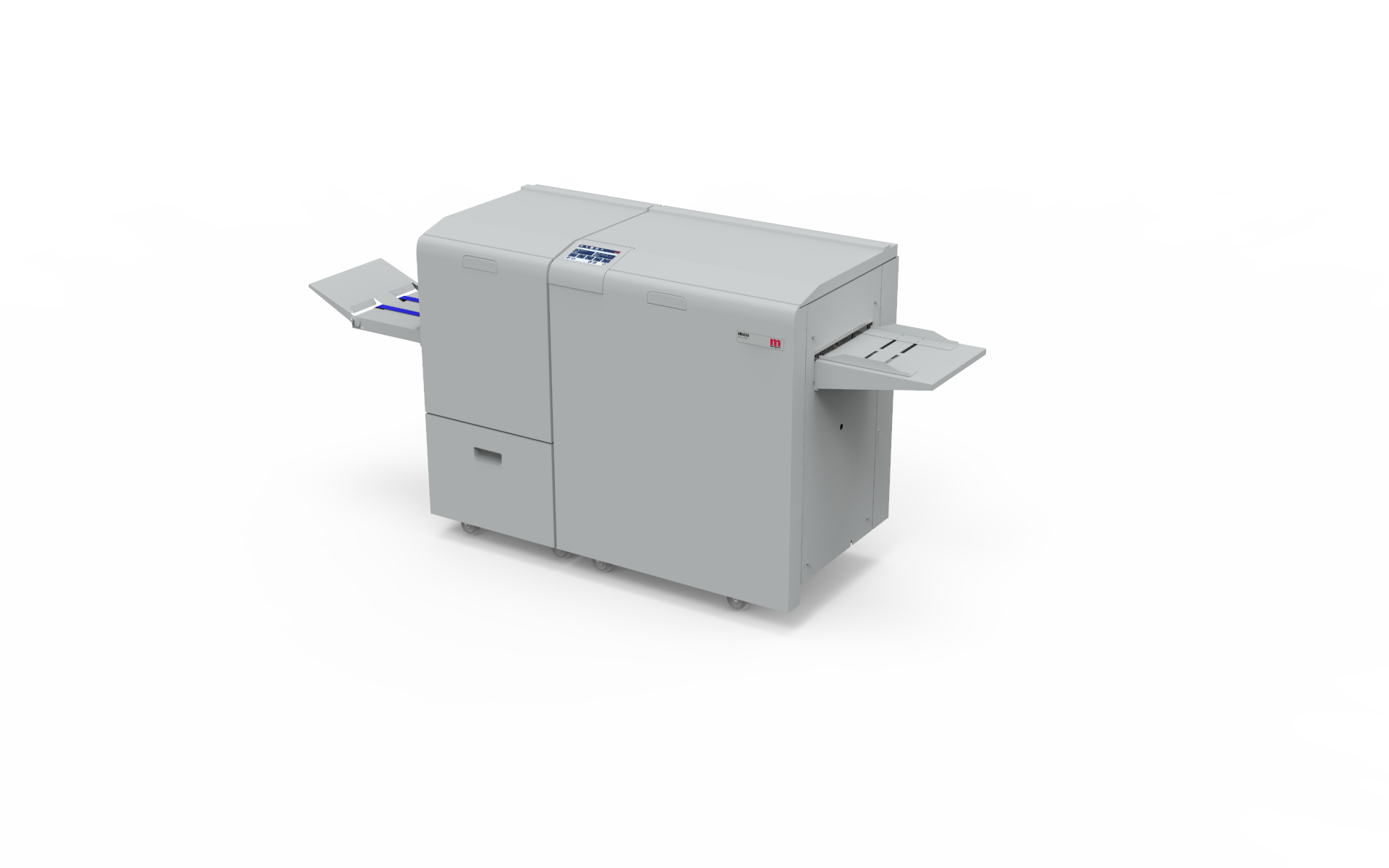

The Morgana BM4035 represents the latest style of booklet maker in the supplier’s range. The product can produce A6 to A4 portrait publications, as well as A4 landscape and large format 297mm x 297mm books. It also has the ability to corner and edge staple as standard.

NPC Print founder and CEO, Natalie Puttock, commenting on this latest purchase, said: “We needed to expand the range of formats that we could produce. Most importantly, the ability to produce long sheets, such as A4 landscape products, a format that has become increasingly popular in recent years – jobs that we have had to send out for finishing. The ability of the new BM4035 to produce this format in-house will give us control of that work, as well as saving us money on outwork.

“Having recently taken the decision to upgrade our digital print device to a new Konica Minolta AccurioPress C4070 engine, the new binder will help us to show off both our print and in-house finishing capabilities to the fullest. The square-back capability of the binder is a feature that we can also promote for higher pagination publications – it gives the impression of a perfect bound book.”

“The binder will initially be manually fed, but as print quantities increase, we know that we can easily add an automated feeder on to the unit for higher productivity.”

The company currently utilise other Morgana products in its post-press section, including a Morgana AutoCreaser, and an Intec ColourFlare device for foiling and laminating, purchased through Morgana.

The Morgana BM4035 is a versatile booklet maker designed to work with low to mid volume digital production printers. It delivers booklets of exceptional quality and is able to feed long printed sheets to produce a wide variety of applications, including A4 landscape booklets, which are becoming an increasingly important expectation of customers.

Commenting further on the purchase decision, Natalie added: “Our previous Morgana binder gave us exceptional service – it never let us down. That reliability meant that we didn’t need to even look at any other machines in the market. Everybody at Morgana – from sales to installation personnel – have been helpful and very professional.”

“Having recently taken the decision to upgrade our digital print device to a new Konica Minolta AccurioPress C4070 engine, the new binder will help us to show off both our print and in-house finishing capabilities to the fullest. The square-back capability of the binder is a feature that we can also promote for higher pagination publications – it gives the impression of a perfect bound book.”

“The binder will initially be manually fed, but as print quantities increase, we know that we can easily add an automated feeder on to the unit for higher productivity.”

NPC Print serves customers ranging from agencies, corporate clients, finance companies, and restaurants, through to local businesses. It operates from 186sqm premises with warehousing facilities, enabling it to offer free of charge stockholding facility for its customers.

The BM4000 Series uses the latest patented Plockmatic technologies to deliver top quality output. The base unit folds and staples booklets, and also provides for corner or edge stapled. It can produce up to 140 pages (35 sheets with the BM4035) or 200 pages (50 sheets with the BM4050). The set positioning mechanism enables the operator to easily adjust the staple and fold position on the fly. Corner or edge stapling is a fast and simple solution, typically used for producing meeting notes, reference documents, or hard copies of PowerPoint presentations.

The heavy-duty staple mechanism is designed for durability, as is maintenance free thanks to a patented solution that eliminates periodic service intervals. Staples are delivered via an easy to change staple cartridge.

Full details of Morgana’s product line-up can be found at: www.plockmaticgroup.com

Editorial article first published in QPP Quick Print Pro: NPC Print Upgrades Morgana Booklet Maker With BM4035 Purchase (quickprintpro.co.uk)

Accent Equity has as of today stepped in as new majority owners of Plockmatic together with Grimaldi Industri. Plockmatic’s management team will continue in their current roles and co-invest alongside Accent Equity and Grimaldi Industri.

Plockmatic is a trusted and well-established provider of innovative document finishing solutions to the global digital print- and packaging industries. The company offers a unique range of in-house developed products which support current macro trends such as increased automation and individual customization of printed materials.

“We are very proud of our 20 years together with Plockmatic and are excited to see Accent enter as a strong investor. We believe they will be a great partner for us to further enhance our journey of expanding our business and strengthen our offerings”, says Salvatore Grimaldi, CEO & Founder of Grimaldi Industri.

“We are very happy for this opportunity to invest in a truly well-managed company and we are impressed how the management team has developed Plockmatic over the years with a successful long-term strategic view. The company is well positioned to continue its growth journey in several different areas. We have a clear target to grow Plockmatic both organically and through acquisitions and look very much forward to working together with the Plockmatic team”, says Oscar Claeson, Associate Partner at Accent Equity.

“The graphical market offers great business opportunities for continued transfer of applications from traditional offset to digital print. With high focus and strong support from our owners, Accent Equity and Grimaldi Industri, we will be able to continue our journey of business development for finishing solutions and other core areas, such as supply chain, marketing, sales and technical support with focus on sustainability. Plockmatic continues to be dedicated in ensuring new and innovative solutions for the market, our partners and customers”, says Jan Marstorp, Group CEO of Plockmatic.

Oscar Claeson (Accent, chairman) & Jan Marstorp (CEO, Plockmatic Group)

Wilson Press & Mail House, Seneca Falls, New York State, USA, “the one-stop shop for design, print and mail”, became the latest printer to install a Morgana BM5050 booklet maker, manufactured by Morgana Systems Ltd, a Plockmatic International post-press product business, in March 2023.

Whilst the company was already using an inline booklet maker, there was a demand for additional booklet making that was not governed by the speed of the print engine. An offline booklet maker would provide for both additional capacity and the ability to bind jobs for those print engines not coupled to a dedicated binder.

“The Morgana system is so user friendly. This system allows us to provide improved job turnaround times. Our team like the ease of use of the BM5050. Its menu driven via the user touch screen, and it presents the operator with straightforward logical choices when setting up the job.”

Rick adds: “With typical production runs of about 2,000 copies, the BM5050 just whizzes through the work, meaning that our turnaround times for jobs have been reduced. Our finishing department is just delighted with the binder.”

The new system at Wilson Press was installed and ready for action from early 2023. With regard to the arrival of the new booklet maker, Rick Ricci said: “We have been familiar with Morgana equipment for some time, so when we were looking to an offline booklet making machine, they were an obvious place for us to look.

Work produced at Wilson Press on the new booklet maker can now include the square-back finish – when a wire-stitched booklet can take on the appearance of a perfect bound product.

Typical throughput at Wilson Press is focused on a core business of designing, printing, and mailing.

Operators can now also compensate for the skew caused when feeding long sheets with a simple adjustment in the user interface, on the fly. Wilson Press can now produce SquareFold booklets in sizes from 4.1 x 5.8” to Letter-sized Landscape, or in the larger Letter-square-format (297 x 297mm).