- Region: Norway +47 23898586

The ColorCut SC7800 Pro-T XL is a superb, and unique, dual tool cutter/creasers, a hybrid blend of flatbed, sheet-fed, tangential and contour cutting technologies, designed to deliver the benefits of each technology in a compact, affordable and productive unit.

This fully-automatic addition to your studio or production line, can produce point of sale, packaging in absolutely any shape you wish, in a highly productive and totally versatile way – all from your own pre-designed and printed artwork!

Equipped with an amazing dual tool head that incorporates a premium flatbed style active TANGENTIAL creasing wheel, makes this device completely unique, enabling you to cut and crease paperboard up to 450 micron and handle a diverse range of media, including paper and synthetics in-between.

Couple all of this easily usable convenience and functionality with the QR code driven workflow for total unattended automation and you have an extremely powerful, flexible system at your disposal, capable of rapidly processing up to 1,000 sheets, even with multiple mixed jobs in the same stack!

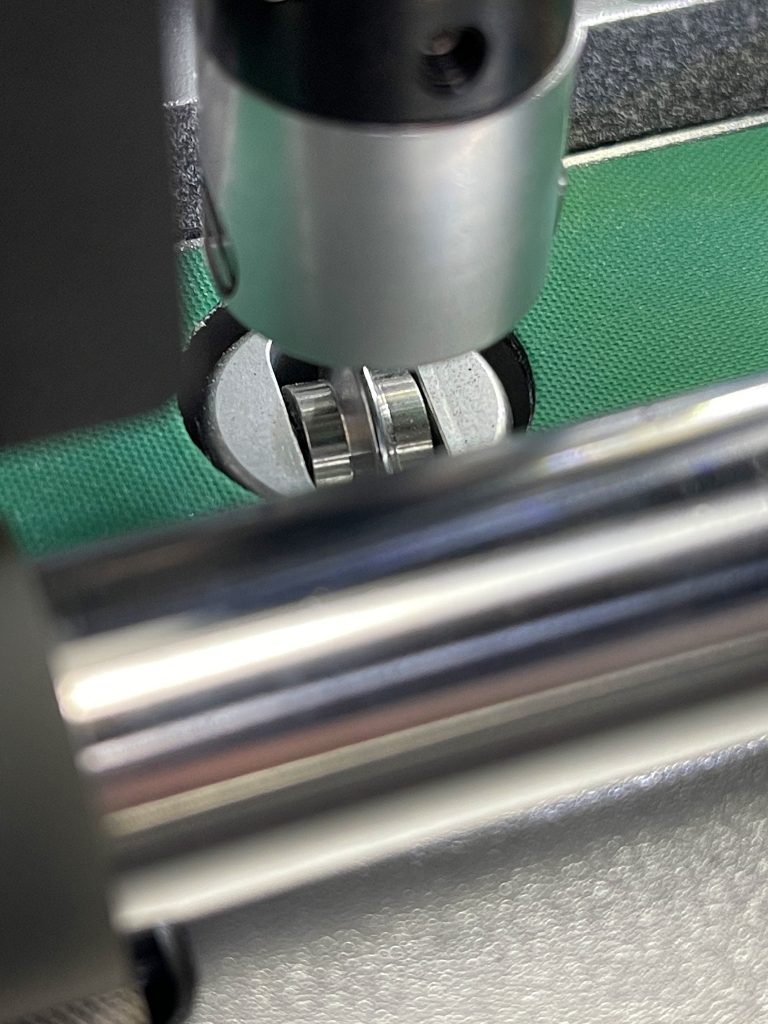

The triple tool head includes 1 passive drag cut and 2 active tangential crease wheels (1 male, 1 female) delivering up to 2,500gf enabling a wide range of media to be finished; FBB, card, papers and synthetics

9th generation Vision3 CCD camera reads and instantly retrieves cut files for every sheet on the fly. Accepts a mixed stack of jobs, cutting one after the other in a seamless and uninterrupted flow

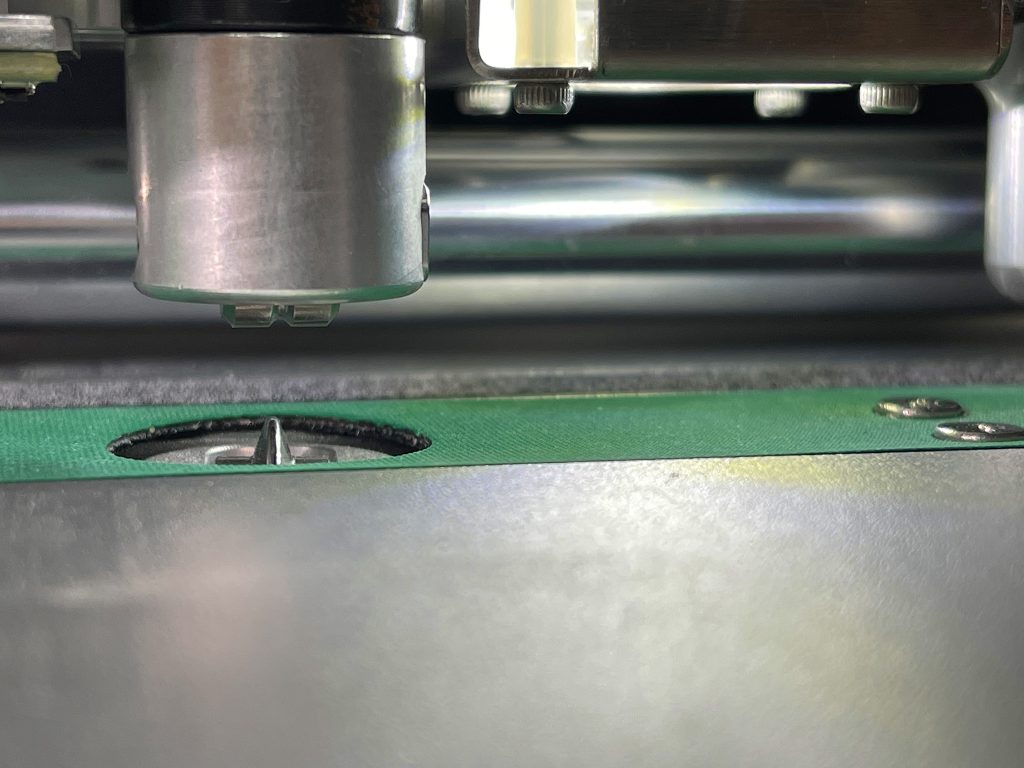

Quad (4) ‘Grip and Drive’ feed system holds media during cutting on both sides of the cutting head, enabling it to cut closer to media edges

Superior cutting strip delivers an optimal surface for cut-through, while creasing is handled by the male and female Creasing wheel ‘forms’ floating above AND below your media.

SmartTags are left in the cut lines to retain the item in the sheet – leaving a tidy and manageable stack of finished sheets in the media catch tray

High-capacity auto feeder works in conjunction with air blade separation and automated jog function, to present every sheet perfectly for the cutter, every time

Standalone production offered with new HELD mode. Load jobs from a USB drive, view and auto scan to cut. This means that repetitive high volume jobs can be run easily without a connection to a computer – no skilled operators required!

*QR codes and SmartMarks are generated as part of the included ColorCut Pro software

The SC7800 Pro-RS XL was designed to deliver unattended operation with particular attention paid to the feeding system to ensure class-leading performance for card or even tricky laminated sheets. The auto feeder accepts up to 900 sheets, which automatically raises and lowers as required. To prevent sheets curling (as a result of a constant air flow to the sides), the machines use a dual automatic air blade that fires a blast of air momentarily into the front of the stack just as the advanced vacuum feed belt lowers to collect the top sheet. To further provide a reliable feed, the vacuum feed belt lifts the media carrying any sheets not pre-separated by the air blade past a pair of dexterous separation fingers which dislodges them. Finally, before advancing the sheet into the cutting engine, the vacuum feed belt ‘jogs’ briefly against the rear paper stop, creating a natural curve that helps ensure even difficult media feeds faultlessly.

The digital triple tool head includes passive contour/drag cut and patent pending-dual (opposing) active creasing wheels applying force individually, for both the cutting and creasing tools.

This combination of tools provides a much wider media handling capability and more defined, smoother crease for thick card up to 450 micron. The individual tool actions are controlled via the included ColorCut Pro 5 Production Studio software.

In common with the entire ColorCut family, the tools can be set to apply exact amounts of pressure and speed, along with total control over the application of cut, crease or perforation of vector artwork lines drawn in Adobe® Illustrator® or CorelDRAW®.

Dual Opposing Tangential technology enables the SC7800 Pro-RS to move a creasing wheel AND a separate creasing groove either side of your media simultaneously. The opposing tools, deliver a traditional looking ‘Male/Female’ crease to enable a more defined, smoother precise crease.

The SC7800 Pro-RS XL models are built on the foundation of our next generation of Ai based ColorCut Pro software delivering new features, functionality, control and automation, redefining how automated cutters can be used, easily, simply and autonomously by providing 2 modes users can employ for cutting files.

In DIRECT mode: ColorCut Pro offers unparalleled flexibility and control over cutting and production from the connected PC. When creating jobs, the ColorCut Pro Client plugin applies an auto-assigned QR code to each design, whilst auto-saving the cutting file (editable) to the ColorCut Pro Job Library.

In HELD mode: ColorCut Pro stores your job parameters, wrapping all the required settings into a custom held mode cut file, that can be transferred to a storage device on the cutter. This enables standalone operation, without the need for the main PC and can be cut at a later date by any operator. The cutter checks the QR code on each sheet, retrieves the associated cut file and proceeds to cut and crease as required – even if the sheet is presented at 180°, reducing operator errors.

The new 7″ immersive touch screen with extensive Info-Control system includes a live camera preview window delivering visual feedback of QR code and smart registration marks scanning.

Plus, feature rich options that provide an advanced level of control over the auto-feeder’s functionality. Useful for certain media that may require special handling or simply to optimise throughput of your chosen media.

The 7 inch immersive touch screen control panel can pivot to suit the angle desired by the operator.

A space-saving media catch tray slides away when not in use and the manoeuvrable stand ensures it is easily accommodated into any working environment.

The ColorCut software seriously enhances productivity. Supplied complete with pre-installed Windows© PC and ColorCut Pro software suite, with a flat screen monitor, mouse and keyboard. Also includes software user licence for 2 additional seats.

The Server Station offers a much more advanced level of control with users benefiting from a host of premium features which make a quantum leap in functionality and productivity.

In the design phase, jobs created by graphic designers using ColorCut Pro Client, are saved into ColorCut Pro’s Job Library.

Production Studio – the core application for production and cutter operation (supplied with cutter). Its easy to use interface offers powerful functions for setting tool force, speed, line actions, feeding and productivity control when used in conjunction with the printed sheets QR code to instantly retrieve the correct cut file to cut your job. Auto generated job numbers can also be used to recall the cut file, enabling an operator to load and send jobs directly to the cutter.

Job Library Manager – acting very much like a RIP workflow, this sophisticated software brings massive functionality to the networked library of cut job files, enabling custom job naming and identification, searching, viewing and even assigning unique or custom actions to specific QR codes or job numbers. One central and synchronised source for all ColorCut users.

A selection of premium label media for optimal performance on our ColorCut Die Cutters*.

*ColorCut Label Media is currently only available in UK & Europe