- Region: United States +1 585 267 7692

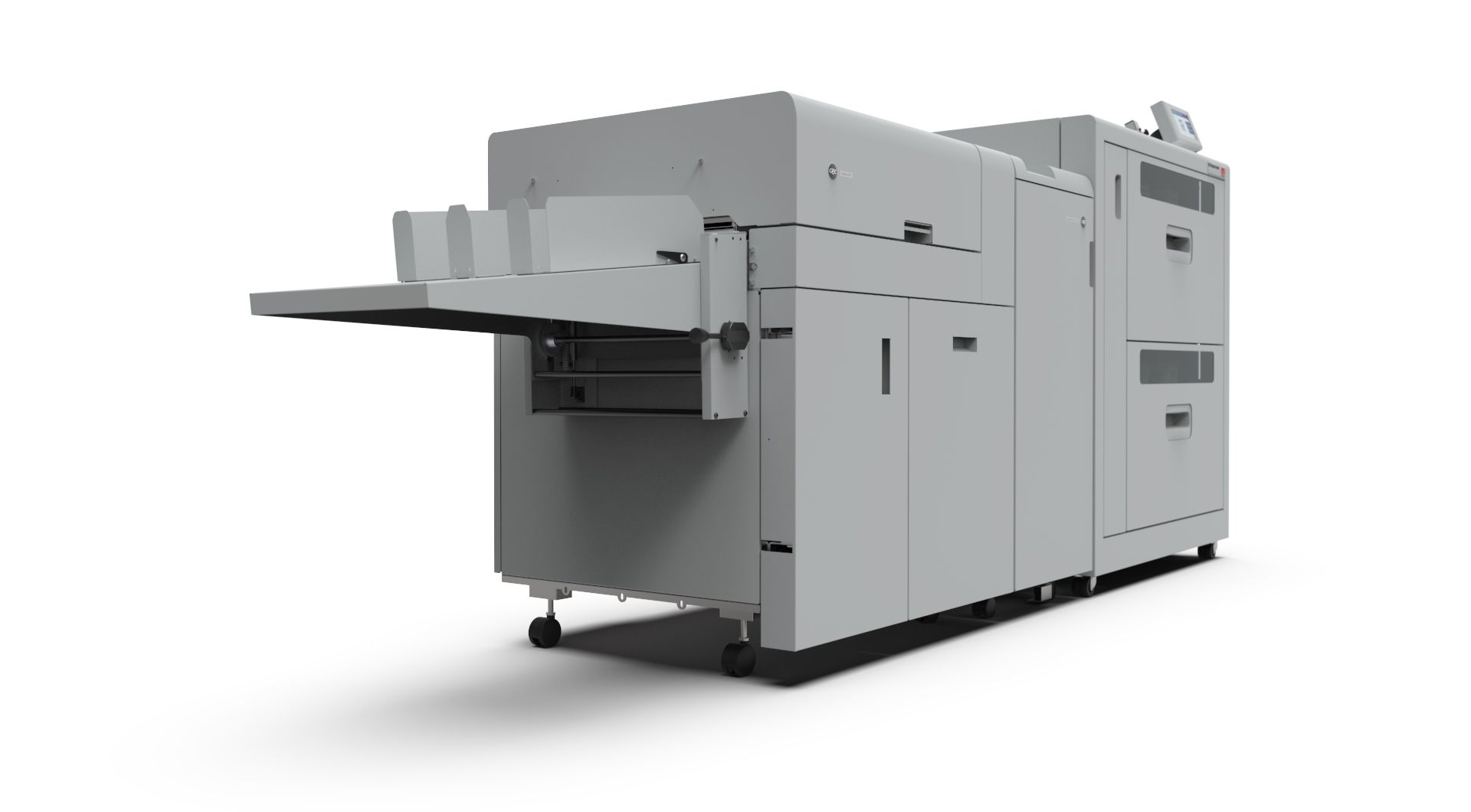

The Morgana DocuBind Pro VFX is a is an innovative solution for all your mechanical binding needs giving much greater productivity than hand fed manual solutions, and much more flexibility than running inline with your digital print engine – allowing it to continue to print at full production speed.

Mechanical Twin Loop™ wire binding is a hugely popular method of assembling documents where there is a need for a book to lay completely flat or a need for pages to be written on. This style of document binding is widely used for education & training materials, notebooks, and calendar production where customers are more demanding than ever and often there is a need for quick turnaround of the documents.

The key elements of the DocuBind Pro are the high speed Morgana VFX vacuum feeder running at up to 144 pages per minute, the StreamPunch VFX heavy duty punching, creasing and perforation module and the innovative eWire VFX twin wire automatic binding solution engineered by GBC.

With its small footprint and wide range of easy to use features, the DocuBind Pro VFX will improve your workflow and reduce labour costs for all your mechanical binding applications.

• Calendars

• Presentations

• Training Materials

• Menus

• Notebooks

• Legal Contracts and Proposals

The Morgana VFX Vacuum Feeder is the latest feeder platform from Plockmatic Group. The key design target of the Morgana VFX is increased ease of use for the operator and enhanced feed reliability. It includes numerous patent pending technologies that have been developed to minimize operator setup time and reduce the requirements for exclusively trained operators.

Key features

• Newly engineered feeder platform from Plockmatic Group

• Holds up to 5400 sheets for long uninterrupted runs

• Automatic bin switching where paper can be loaded on the run

• Simple to program and use

• Automated feeding performance across a wide range of media

The StreamPunch VFX is a fully automatic hole punching unit which utilizes a wide range of die sets for multiple hole types, even for basic creasing or perforation of printed sheets. Pages can be punched to be automatically bound in the eWire system. A bypass through the eWire VFX enables 2-up double punching of sheets minimizing printing time and cost. The dies are heavily engineered for long life and durability. Sheets up to SRA3 can be processed in stock weights up to 300gsm.

The eWire VFX completes the binding process feeding the wire from spools conveniently located inside the main cabinet of the machine. The wire is fed and cut to length for the required document, closed automatically and the finished book is delivered into a catch stacker. Wire is available in 6 different spool sizes for documents up to 10mm thick or approximately 100 pages. The wire is also available in white, black and silver to match the required finish of the document.