- Region: International

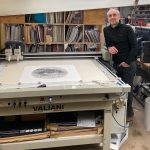

Apprintable offers a same day print service for London based clients, and runs a web-to-print service for clients nationwide. The company is following a clear growth strategy centred around its previously announced Ricoh digital print engine. With regard to this latest post-press addition, Peter Haddad, Managing Director of Apprintable, said: “We were spending a fair bit on outsourcing lamination; it made good business sense to keep that money in-house, and bring control of job back into our own hands. Because of the investment in the Ricoh press last year, we’ve been able to bring a lot more production in-house and bringing laminating back here was the obvious next step.

“We had a small Chinese manufactured machine most recently that we were using for very urgent jobs, but that was a very manual process, and the unit was also difficult to use. It got the job done for the very short run work, but the quality does isn’t even close to that from the Morgana unit.”

Designed for easy operation, the Laminator Pro 450 is a unique high-pile automatic feed laminator. It features an integrated compressor and pneumatic system for high quality print lamination up to 450mm working width. This revolutionary compact machine combines speed and ease of operation with quality.

This deep pile, automatic suction feed system can achieve speeds of up to 1,875 of SRA3 sheets per hour. A micro-perforation and scissor roller cutting system provides for perforation and separation of sheets. The Laminator Pro 450 is ideal for the on-demand printer. It is both easy to set up and very versatile, being capable of foiling and spot gloss as well as straightforward laminating.

“We bought our AeroCut Prime from Morgana just before Christmas. It was ordered and delivered within a week. I was so impressed by Morgana and their focus on what the client needs, as well as their ability to assist us so speedily. I can just trust those guys.

“I was impressed by the fact that they didn’t want to sell me something that I didn’t need, such as an higher spec version of the Prime. I felt that I could really trust them and that they cared about my business – their representative used to be a litho printer. We then bought a Canny P50 bander from Morgana following the Prime purchase. It made good business sense to go back to Morgana for this latest purchase.

“I did look at other laminating products, just to confirm my selection. There was one with a separate feeding unit – but that gave me doubts because I have seen disconnected systems fail badly. It made sense to stick with Morgana as our finishing machine provider. They gave a fantastic demo of the product, and that gave me a lot of confidence in the purchase.”

With the machine now installed and running, Peter adds: “The speed, the ease of webbing it up, and the fact that we can just let it run almost completely unattended have been the obvious benefits for our productivity.” With regard to the work that the new machine will be used for Peter said: “Laminated business cards, flyers, and POS work, as well as more unusual products such tent cards and coffee cup sleeves. We can use matt, gloss, and soft touch finishes, and will also be adding matt biodegradable material, in keeping with our sustainability focus.

“The Laminator Pro 450 can also produce digital foiling, and this is something that we are currently experimenting with, and will be bringing that work in-house too. It was the foiling capability that really helped to clinch the deal for me. It costs so much to outsource foiling compared to the actual raw material costs involved, so we see this as another huge opportunity.”

Overall capital expenditure for products from Morgana in the past three months has totalled £48,000. “It’s a great company to work with. They understand what we need because their team has worked with printers of our size for decades. The individuals that we have met know printing and can understand what we need.”

“We are now already looking at new premises for 2023. Our recent equipment purchases have filled our current factory!”

“The Laminator 450 and 450 Pro offer a range of printers the ideal in-house laminating solution. Apprintable is a growing business that is looking to bring as many services in-house as they can. Peter and the team can appreciate that’s where the margins for printers can lie. Using external suppliers just eats into your profits.”

Apprintable is a London printing company with a graphic design service busines and an on-line portal for a variety of printed products. The company specialise in print for businesses across the country. An in-house digital printing service is what helps to make Apprintable an agile and flexible service provider with different delivery options that will suit customers’ needs, from express printing to same day print delivery in London. There is no need for you to look no further!

No matter what printing and design services a brand needs, Apprintable can assist with high-quality printing services that are sure to go the extra mile. A focus on customer service is what makes the company’s ratings exceptional, with product delivered to the highest of standards.

For further details see the https://www.apprintable.com web site.

Pelican Print invests in high-end Morgana booklet maker

Pelican Print Ltd, the Aylesbury-based digital, litho, and large-format printer, has invested in a Morgana PowerSquare™ 224 booklet maker for the production of SquareBack™ books of up to 224 pages for the company’s digital print operation.

The Morgana PowerSquare 224 booklet maker is perfect for the binding of high pagination or heavier stock publications, but is equally at home with smaller formats. The unique SquareBack finish for books or booklets is able to carry print on the spine, giving an appearance similar to that of perfect bound books. The finished shape makes books and booklets easier to handle, stack, store, and pack.

“One of our major clients has added a number of sites to its expanding business. As a result, the number of publications that they are ordering has grown significantly. This has meant that we had to decide how we were going to best solve the increase of work in the post-press area of our digital workflow.

“We had started to review our digital finishing capabilities prior to the pandemic, as we had been shuttling work from our digital production factory over to our litho building on the other side of Aylesbury. That then often meant interrupting a longer run on our Muller Martini stitching line in order to produce a short run job. Higher pagination work might have involved sending the work out to a trade finisher for perfect binding.”

During a visit to a Morgana open house event in Milton Keynes at the end of 2021, Gary was introduced to the Morgana SquareBack 224 product. “The machine seemed to deliver everything we needed – the combination of the four processes of stitching, folding, spine forming, and trimming in one unit, with the option to produce SquareBack books of up to 10mm thick.”

Whilst Gary and his team were familiar with the solid build and typical ease-of-use of Morgana products, as well as the company’s efficient support team, comparisons with competitive products were important. Following a detailed analysis Gary was able to make his recommendation to Pelican Print’s Managing Director, Scott Brookes.

“Gary investigated the options, and the Morgana PowerSquare was the machine that ticked all of the boxes,” said Scott. “When I saw the machine in action I was immediately impressed by its capabilities and its productivity.

“The SquareBack feature on saddle-stitched work really stood out for me. It means that we can now produce a product with all of the visual appeal and storage benefits of a perfect bound book, but at a nearly half the price, and in a fraction of the time that it would take to be produced by conventional perfect binding.”

With the machine now in action, Gary is impressed once again with the ease-of-use: “It’s very easy to set up the machine – and that’s essential when you are dealing with short-run work. We can be in production in five minutes – something that might have taken half-an-hour on the more complicated Muller Martini equipment. Typically, we might only be producing 50 or 100 books, so those runs can be produced in just 10 or 15 minutes.

“We run a variety of publication sizes as well, and A6 sized work goes through the machine just as easily as the more regular A5 or A4 products.”

The maximum finished book thickness of 10.4mm (approx. 208 pages of 80gsm, or 224 pages of 70gsm), is nearly double that of alternative conventional booklet making machines, so it is ideally suited to higher paginations or thicker stocks, whilst still being very capable of producing a variety of sizes and sizes of booklets, right down to a sheet size of 120 x 200mm.

The Morgana PowerSquare 224 stitch head can insert from one to six stitches in the spine of printed work. The stitch head and clincher are static, with the sheets moving to the stitch head. This means the stitch head and clincher never have move, so alignment and stitch quality are consistently good.

Up to six staples can be applied to booklet set, meaning that smaller format work can be printed 2-up or 3-up, and subsequently cut to size after stitching for highly efficient production. It also features fully automated settings for different popular book sizes and paginations. The system provides for variable stitch-leg length for different book thickness, and a variety of wire colours are available. This means that it is now possible for the coloured stitches to be matched to the print on a spine.

All of this helps to make the PowerSquare 224 a fast and cost-effective alternative to perfect or tape binding. The unit at Pelican Print is hand-fed, but Morgana’s VF and VFX feeders available as options.

Many digital print applications use heavier stocks, and need the flexibility to produce a wide range of finished books from a single process, with limited operator intervention. The PowerSquare is a perfect match with its ability to handle publications printed on stock from 60gsm to 400gsm.

Pelican Print is based in Aylesbury and has been providing printed materials to customers all over the UK since 1998.

All main services are on site, which means the company has full control and is able to provide a very reliable service, from start to finish. Pelican Print prides itself on quality and excellent customer service, with the help of some 18 staff, it can respond quickly to customers’ needs and make sure that projects run smoothly, however urgent the deadline.

Staff listen carefully to what customers need and keep them up to date with progress.

Experienced print buyers can receive full details of the capabilities of the company’s equipment if desired, including what is happening in our ever-expanding digital site.

For further information please visit the https://www.pelicanprint.co.uk web site.

Leading Southampton general print business, Colour Company, has upgraded its creasing and folding capability by installing a Morgana DigiFold Pro XL from Morgana Systems.