- Region: Norway +47 23898586

Building on the successful SC6000 series, the new SC6500 offers a new ‘No Wires’ working environment.

The SC6500 is a compact dual tool digital cutter offering a highly advanced and reliable high capacity (1,000 sheets) auto-sheet feeder to cut and crease light sheet card (up to 350micron), or labels, to any shape without any set up costs.

With its unique and reliable vacuum belt feeder, the SC6500 can be left to cut unattended, while the camera registration system automatically retrieves cut files by reading the QR codes on each sheet.

The ‘No Wires’ working environment allows users to operate the cutter without being connected to a PC or to learn a new software program. This especially suits the production and manufacturing environments, where a fast turn around time is essential.

Targeted for busy print departments, seeking an affordable, high-capacity device for complete unattended cutting production, the SC6500 combines ultra-reliable feeding with an instant job retrieval system and flawless high-speed cutting and creasing. This compact free-standing device is conveniently mobile and will be easily accommodated in any print shop.

The SC6500 has been designed to provide unattended operation with particular attention paid to the feeding system to ensure class-leading performance for card, vinyl labels or even tricky laminated sheets. The SC6500’s auto feeder accepts up to 1,000 sheets, which automatically raises and lowers as required. To prevent sheets curling, as a result of a constant air flow to the sides, the SC6500’s uses an automatic air blade that fires a blast of air momentarily into the front of the stack just as the advanced vacuum feed belt lowers to collect the top sheet using pneumatic suction. To further provide a reliable feed, the vacuum feed belt lifts the media carrying any sheets not pre-separated by the air blade past a pair of dexterous separation fingers which dislodges them. Finally before advancing the sheet into the cutting engine, the vacuum feed belt ‘jogs’ briefly against the rear paper stop, creating a natural curve that helps ensure even difficult media feeds faultlessly.

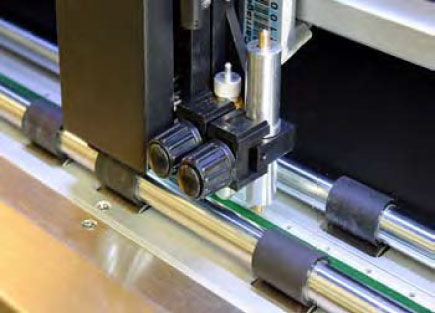

The digital cutting head can apply up to 760gf, individually for both the cutting and creasing tools. Their actions are controlled via the included ColorCut Pro software. In common with the entire ColorCut family, the SC6500 can be set to apply exact amounts of pressure and speed, along with total control over the application of cut, crease and perforation of the vector artwork lines.

The space-saving media catch tray slides away when not in use and the manoeuvrable stand ensures it is easily accommodated into any environment. The 7 inch immersive touch screen control panel is housed within an articulated module which can pivot to suit the angle desired by the operator.

When creating jobs, ColorCut Pro applies an auto assigned (editable) QR code* to each design, whilst auto-saving the cutting file to the ColorCut Pro Job Library.

Jobs with QR codes can be cut at a later date by any operator – no need to search for which file to cut – no specific computer application skills required! The SC6500 checks the QR code on each sheet, retrieves the associated cut file and proceeds to cut and crease as required – even if the sheet is presented at 180°. Choose to cut a single sheet or even thousands on an unattended run.

The Vision3 CCD camera has an 8th generation sensor with enhanced sensitivity to read even white QR codes and SmartMarks, when applied on dark media.

The ColorCut software seriously enhances productivity. Supplied complete with pre-installed Windows© PC and ColorCut Pro software suite, with a flat screen monitor, mouse and keyboard. Also includes software user licence for 2 additional seats.

A selection of premium label media for optimal performance on our ColorCut Die Cutters*.

*ColorCut Label Media is currently only available in UK & Europe