- Region: United States

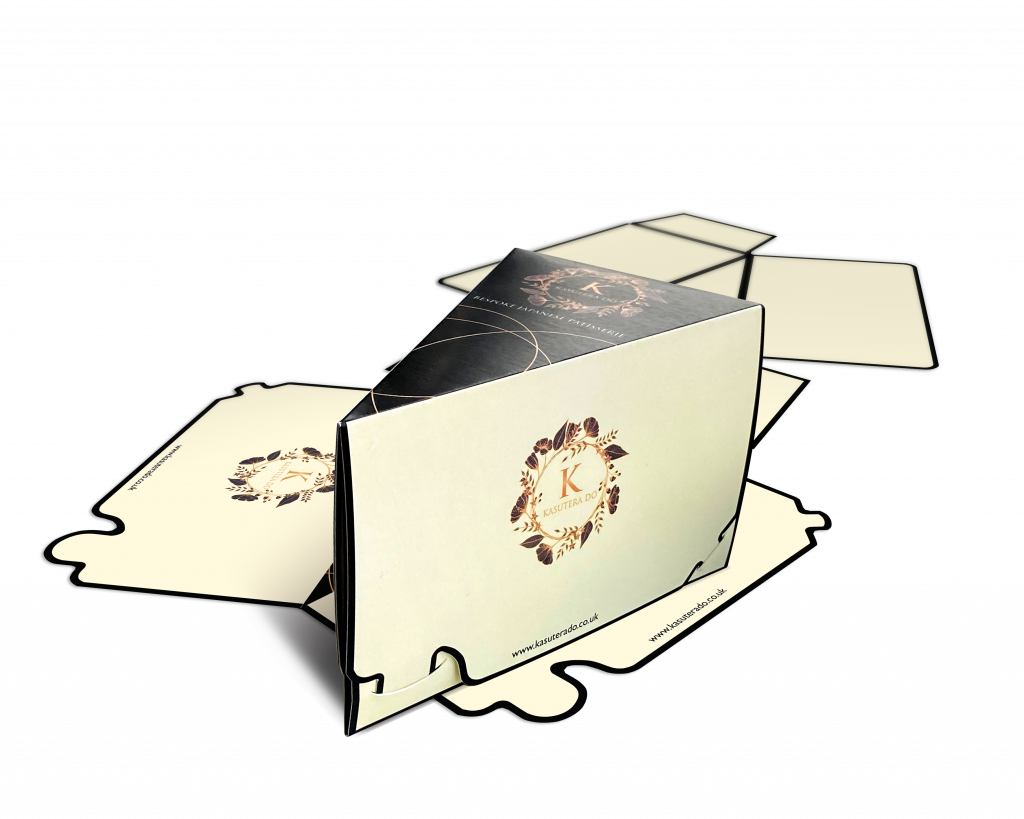

Morgana ColorCut SC7000 Pro-T – These exceptional dual-tool cutter/creasers combine flatbed, sheet-fed, tangential, and contour cutting technologies into a single compact, affordable, and highly productive unit. This hybrid design leverages the best features of each technology, offering unparalleled versatility and efficiency.

Fully automated and designed to integrate seamlessly into your studio or production line, this innovative machine can create point-of-sale displays, packaging, and kiss-cut labels in virtually any shape. Using your pre-designed and printed artwork, it delivers exceptional productivity and flexibility.

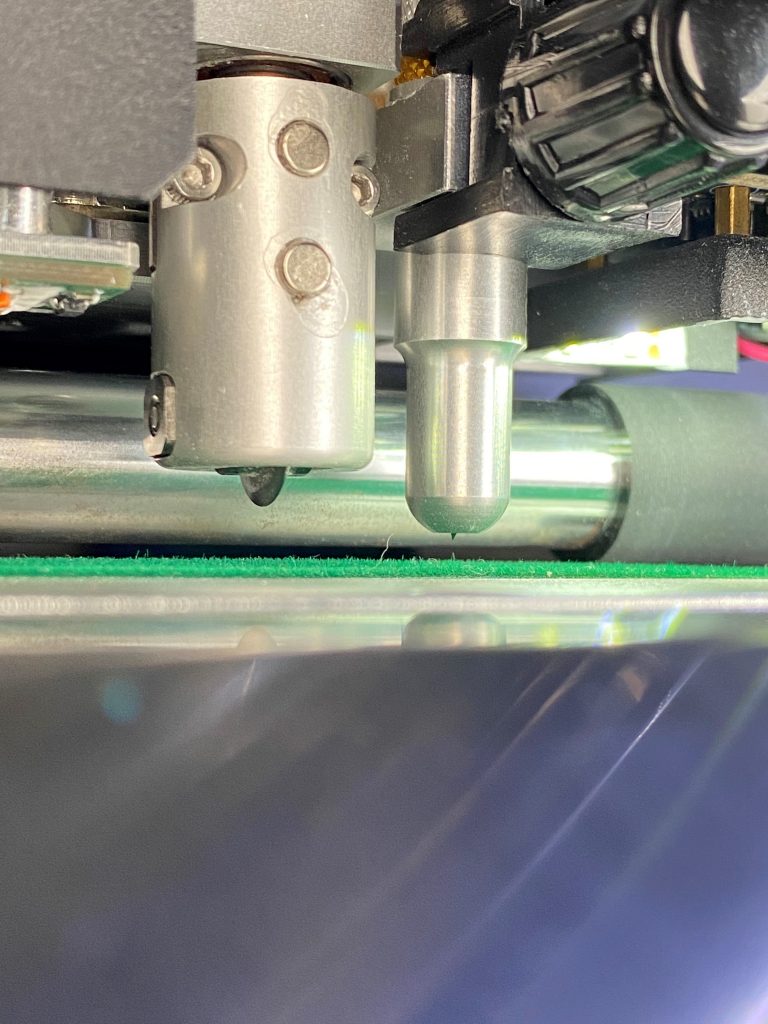

At its core is a remarkable dual-tool head featuring a premium flatbed-style active tangential creasing wheel, making it uniquely capable of cutting and creasing paperboard up to 450 microns. It effortlessly handles a wide variety of media, including paper, synthetics, and everything in between.

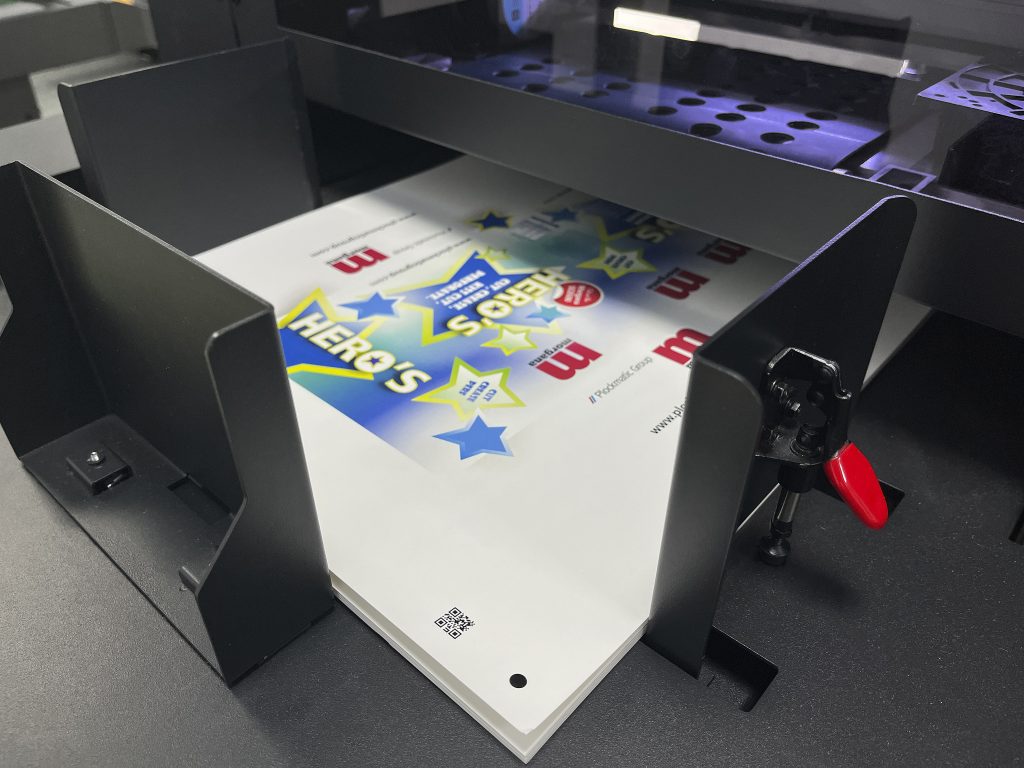

Adding to its versatility, the system is driven by a QR code-enabled workflow for fully unattended operation. It can efficiently process up to 1,000 sheets, even when handling multiple mixed jobs in a single stack. This powerful and flexible solution is ideal for businesses looking to streamline their cutting and creasing processes while maximizing productivity.

QR codes and SmartMarks are effortlessly generated using the included ColorCut Pro software plugin.

Designed for busy print departments in need of an affordable, high-capacity solution for fully unattended cutting production, the SC7000 Pro-T delivers exceptional reliability and efficiency. Featuring ultra-reliable feeding, an instant job retrieval system, and precise high-speed cutting and creasing, this device ensures seamless operation and outstanding results.

Its compact, free-standing design makes it conveniently mobile and easy to integrate into any print shop, providing a space-saving and versatile addition to your production workflow.

The digital dual-tool head on the SC7000 Pro-T features passive contour/drag cutting combined with active tangential creasing wheels, each applying force individually for cutting and creasing operations.

This innovative dual-tool head and advanced tangential control make the SC7000 Pro-T a powerful solution for achieving superior cutting and creasing accuracy across a wide range of applications.

The ColorCut software seriously enhances productivity. Supplied complete with pre-installed Windows© PC and ColorCut Pro software suite, with a flat screen monitor, mouse and keyboard. Also includes software user licence for 2 additional seats.

The cutter checks the QR code on each sheet, retrieves the associated cut fi le and proceeds to cut and crease as required – even if the sheet is presented at 180°, reducing operator errors.

A selection of premium label media for optimal performance on our ColorCut Die Cutters*.

*ColorCut Label Media is currently only available in UK & Europe